Did you know that your choice of warehousing service can make or break your business?

According to studies, a delayed shipment reduces your chances of repeat business by 87%. In comparison, a positive delivery experience increases your chances by 79%.

Providing a seamless and satisfactory delivery experience is crucial for building customer loyalty and driving repeat business. That’s why you need to choose the right warehousing service that prioritizes timely and reliable delivery.

This guide provides clear insights on choosing the right warehousing solutions for your business. Learn about the different types of warehousing services and how to handle service-level agreements.

We provide all the crucial details you need to make smart decisions that will streamline your supply chain and grow your business.

Warehousing: The Unsung Hero of Your Supply Chain

Warehousing may seem like a simple concept at first glance. But as the home to your most valuable asset (your inventory) and a pivotal player in your supply chain, warehousing is actually a key function of your brand.

Want to increase customer lifetime value with reliable delivery? Download Ware2Go’s eBook to know how.

What Is Warehousing?

‘Warehousing’ is where your inventory is stored, as well as the systems and protocols that warehouse staff employ to ensure proper storage, processing, and monitoring of inventory levels.

Some warehouses also offer services that enhance product handling, including order fulfillment, labeling, kitting, and packaging. They take security measures to protect against theft and damage and ensure the integrity of the stored goods until they reach their final destination.

Benefits of Warehousing

Outsourced professional warehousing offers many advantages for businesses, such as cutting costs, boosting security, and sharpening accuracy. Here are the specific reasons to utilize professional warehousing services if you sell inventory.

1. Improved Order Accuracy

Imagine a customer’s frustration when receiving the wrong item or a damaged product. With advanced warehouse management systems (WMS), you minimize your chances of errors through features like:

- Real-time tracking that ensures inventory levels and movements are constantly updated, reducing mistakes in order fulfillment.

- Automated stock management that reduces human error in picking processes and data entry, improving accuracy in inventory records and order delivery.

From automated systems to streamlined picking and packing processes, every step is optimized for accuracy, ensuring your customers get exactly what they ordered every time.

2. Enhanced Inventory Management

Real-time inventory updates via tracking technologies keep you informed about accurate stock levels. Coupled with strategic storage placement, the warehouse maximizes space usage, minimizes waste, and ensures the right levels of inventory to meet customer demands.

3. Cost Efficiency

Outsourced warehousing helps reduce cost through optimized storage solutions and bulk operations. By bringing various activities like inventory management and order fulfillment together at one location, warehousing simplifies management, reduces complexity, and cuts down on delays and extra costs.

Additionally, strategically placed warehouses close to key suppliers or main customer areas minimize transport costs and speeds delivery. This helps move goods faster and lowers transportation expenses, making the whole supply chain more cost-effective.

4. Increased Security

Strategic warehousing ensures the protection of your goods through robust security measures and environmental controls. Surveillance systems and restricted access prevent theft, while climate controls safeguard sensitive items from damage.

Additionally, risk management protocols, like fire safety systems, provide further security against potential hazards, keeping your inventory safe and well-maintained.

5. Flexibility in Supply Chain

Market demands fluctuate, but your warehouse can meet the challenges head-on with scalable operations and adaptable facilities. Whether you need to expand storage space quickly, increase the speed of order processing during peak times, or adjust inventory levels to match current demand, your strategic warehousing solution must be designed to handle these changes efficiently.

6. Strategic Location Advantages

Proximity to key markets is critical for speedy deliveries. By choosing strategically located warehouses near major shipping routes and urban centers, you can reduce delivery times and costs while making the most efficient use of your distribution network.

Types of Warehousing Services

If you’re considering using professional warehousing services for your business, it’s essential to understand the various types of services available and how they can benefit your operations. Let’s dive into the different aspects of warehousing services, from inbounding and storage to picking, packing, and shipping, so you can make an informed decision when choosing a warehousing partner.

A fulfillment center (FC) or 3PL provides comprehensive storage, fulfillment, and shipping services. For the purpose of this guide, we’ll refer to a full-service storage and fulfillment center as a warehouse.

1. Inbounding and Receiving

Inbounding covers the process of receiving inventory at a warehouse, starting when items are shipped from the supplier. This begins with an Advance Shipment Notice (ASN), which lists the expected items and quantities. This notice is usually through an Electronic Data Interchange (EDI) as soon as the goods are shipped.

When the inventory arrives at the warehouse, the ASN allows the warehouse team to prepare by allocating the right amount of space and staffing. This preparation helps ensure that all items are correctly accounted for and stored, setting the stage for efficient inventory management.

The quicker inventory is inbounded and stocked, the quicker you can start selling and shipping — turning your inventory into revenue.

A qualified warehouse partner will prioritize dock-to-stock time,or the time it takes to receive and store inventory so it’s ready for shipment. A dock-to-stock time of 48 hours or less ensures more accurate inventory counts and quicker turnaround times so you can sell your inventory immediately.

2. Warehousing Storage Services

If your products require temperature control, humidity control, cold chain, or serialization, it’s essential to thoroughly vet potential warehouses to ensure they’re adequately equipped for your product requirements.

If you deal with perishable goods or adhere to specific inventory valuation protocols like Last-In, First Out (LIFO) or First-In, First-Out (FIFO), choosing the right warehouse partner is essential. They need to be equipped with space, the right tracking systems, and skilled labor to handle your products appropriately.

For FIFO, ideal for perishables, you need a partner with advanced inventory tracking to ensure the oldest stock is used first, minimizing spoilage. For LIFO, suitable for non-perishables, your partner should manage and access the most recent stock efficiently, helping manage costs amid price changes.

If you partner with a 3PL network for warehousing, they’ll do the heavy lifting of inspecting the warehouses and negotiating SLAs. They’ll also monitor KPI’s to hold the warehouses accountable and work with the warehouses to resolve issues and improve efficiency.

Fast-moving SKUs should be easy to access, and products should be stored to reduce the number of step pickers as they move through the warehouse.

Proper slotting ensures fewer picking errors and better fulfillment rates, as shown in the video below.

3. Pick, Pack, and Ship Warehousing Services

Picking and packing refers to pulling inventory from the shelves and packing it into boxes once an order has been received.

A tech-enabled warehouse will have a WMS system with double-verification for pickers to ensure against mis-picks. This saves you both time fielding customer complaints and saves on re-stocking or writing off returned items.

The warehouse should provide shipping through a reputable carrier, especially considering Amazon’s announcement that carrier names must be added to orders and all tracking information will be verified by Amazon.

Carrier pickups should be scheduled daily, and the best warehouses will have all orders received before the daily cutoff time ready for pickup on the same day.

4. Packout Procedures

Proper warehouse packout procedures are vital to ensuring the safety of your products in transit. Items that arrive to customers damaged can result in negative reviews, costly returns, and inventory loss.

Ultimately, your brand equity is at stake regarding proper packout procedures.

Hydrogen water brand, HyVida, saw first-hand how damaged shipments can affect Amazon reviews. While Fulfillment by Amazon (FBA) packed and shipped their Prime orders, HyVida’s customers complained that 1 to 4 cans arrived damaged in every shipment.

The brand’s only negative Amazon reviews were related to damages, while reviews related solely to their product averaged 4.9 stars.

HyVida switched to Ware2Go, and the latter created a custom packout solution that considered factors such as product type, size, and fragility. This solution eliminated their damage complaints and garnered positive reviews on Amazon from customers who noticed the change.

5. Shipping

Shipping your products efficiently ensures a positive customer experience that drives brand affinity and repeat purchases. Partnering with a fourth-party logistics provider (4PL) like Ware2Go can streamline this process considerably.

We help coordinate the logistics and dispatch accurately and swiftly, often securing negotiated shipping rates that can save you money. For example, at Ware2Go, we leverage our strategic partnership with UPS to secure preferred UPS pickup times and guaranteed 1-2 day ground delivery rates for our clients.

Take the case of Cephalofair, for example. After a record-breaking crowdfunding campaign, they faced the monumental task of delivering 62,000 orders of their new board game, Frosthaven. With the help of Ware2Go, they exceeded their delivery promises.

Ware2Go handled everything from ocean freight to final mile delivery, proving that the right 4PL can turn even the most daunting shipping challenges into a success story. This partnership allowed Cephalofair to focus on what they do best—creating great games—while Ware2Go ensured timely delivery across North America.

6. Kitting

Kitting is a handy technique that bundles multiple products into one package for sale. For example, if you sell photography equipment, you might bundle a camera, a lens, and a carrying case into one SKU. Subscription boxes are a popular way in which kitting is used these days.

This method works well for items often bought together, as it helps boost your sales by increasing the average order value (AOV). Plus, it makes the whole fulfillment process smoother and faster because these packages are ready and can be immediately shipped as soon as the order is placed.

This pre-packing saves time and streamlines your operations, allowing you to handle orders more efficiently. By partnering with a skilled third-party logistics (3PL) provider, you can use custom kitting and bundling services that add value.

7. Cross Docking

Cross docking minimizes storage time by transferring products directly from incoming to outgoing trucks. It’s beneficial in some cases, such as when there’s a backorder and you must fulfill orders quickly. This method cuts down on handling costs and shortens the delivery timeline, making it a smart strategy for products that need to move rapidly through the supply chain.

8. Returns Processing

With an average return rate in eCommerce hovering between 20% and 30%, returns management, also known as reverse logistics, keeps customers happy and inventory accurate. This process includes thoroughly inspecting, sorting, and deciding the fate of each returned item—ensuring they’re either restocked or disposed of according to your standards. You must partner with a 3PL network with solid returns processing capabilities.

Especially when dealing with high-value items, your third-party logistics (3PL) partner must keep you in the loop about the condition of returns. You need to know whether an item can be repaired and resold, which can significantly impact your bottom line.

9. Special Projects

Special projects in warehousing often involve handling unique product launches, major sales events, or significant promotional partnerships that require meticulous coordination. For these operations, it’s crucial to have warehousing strategies and services that can quickly adapt to sudden changes in demand and ensure all necessary products are ready and available. It ensures a smooth event without any hiccups.

Take the case of 100 Thieves and their launch of Juvee, a new energy drink. They needed fulfillment services that could handle the surge of orders expected from their enthusiastic fan base immediately following the product’s announcement.

By partnering with Ware2Go, they utilized a network that enabled efficient 1-2 day shipping ground shipping across most of the U.S. This partnership ensured that as soon as the company announced Juvee was announced on Twitch, thousands of orders were processed rapidly, maintaining an impressive average fulfillment time of just 8 hours.

10. Inventory Management

Effective inventory management keeps the right amount of stock on hand. Regular checks, or inventory cycle counts, are crucial. They help you catch any mismatches or missing items early, preventing the headache of running out of stock when customers want to buy—or, just as tricky, having too much stock just sitting there.

Let’s say you run a shop that sells seasonal sports gear. By doing regular inventory checks, you can see which items fly off the shelves and which don’t. Keeping on top of your inventory through a WMS, you’re always prepared to give your customers what they want, when they want it, without tying up your cash in gear that’s not moving.

Understanding Warehouse Management Systems

Now that you know what warehousing is and the kinds of warehousing you could avail, let’s dive into the world of warehouse management systems (WMS) and why you need them.

What Is a WMS?

A WMS is software that connects your warehouse to your sales channels, optimizing inventory management and distribution. It allows you to maximize your profits by streamlining processes, improving inventory accuracy, and enhancing order fulfillment efficiency.

Additionally, a WMS supports real-time data analytics, facilitating better decision-making regarding stock levels, warehouse space utilization, and overall operational strategies.

It automates warehousing and fulfillment processes through:

- Direct shopping cart integrations

- Marketplace integrations (like Amazon and Walmart+)

- Electronic Data Interchange (EDI) connectors

Why Use a WMS?

Merchants need a digital warehousing solution like a WMS to keep up with the demands of the digital sales channels. Consumer shopping patterns have dramatically shifted toward online shopping, with most shoppers using multiple channels, such as e-commerce websites, mobile apps, and social media platforms, before finalizing a purchase.

A WMS integrates with all sales channels, providing a unified and automated solution for multichannel fulfillment. This integration ensures that inventory is accurately tracked and orders are efficiently fulfilled across all channels, meeting the demands of today’s digital shoppers.

When searching for the right Warehouse Management System for your business, prioritize systems that automate processes like:

- Order management

- Warehouse locations

- Delivery tracking

- Inventory management

These automations create a low-touch fulfillment workflow that allows your team to focus on your core competencies rather than managing fulfillment and inventory statuses. The most robust WMS will also manage multiple transit modes from Less Than Truckload (LTL) to small parcels.

Digital Warehousing for eCommerce

eCommerce sellers especially need flexibility in a digital warehousing solution. 90% of customers need order tracking, 80% want delivery updates, and 39% want daily status updates from their online shopping experience and order fulfillment.

A digital warehouse will automatically send order status updates to consumers and include tracking information through a reliable carrier. A carrier is the shipping or transportation company, such as FedEx or UPS, that is responsible for delivering goods from the warehouse to the end customer.

This will reduce the number of customer support interactions your team has to process and give customers a sense of security with your brand.

Why You Need Warehousing Service Level Agreements (SLAS)

A warehousing service level agreement, or SLA, is a formal commitment between a warehousing company and its client where the service standards and expectations are outlined.

The SLA outlines what the client can expect from the warehousing company, so that both parties are clear on the scope and quality of the service.

SLAs should be a major consideration when choosing a warehousing partner.

Finding a warehouse that offers competitive SLAs in the areas listed below will help you provide an exceptional customer experience and keep your inventory moving rather than eating up margins with storage costs.

Here are the key SLAs you should prioritize:

- Fulfillment accuracy

- Dock-to-stock time

- On-time fulfillment

- Cycle count accuracy

It’s often difficult for fast-growing brands to negotiate for top-tier SLAs. Large warehouses often focus their efforts on keeping high-volume merchants happy, and fast-growing brands may feel lost in the shuffle if they can get their inventory into a top-tier warehouse at all.

That’s why many growing brands turn to on-demand warehousing partners, who aggregate the Average Daily Volume (ADV) of multiple merchants when negotiating rates.

This way, merchants of any size can compete with high-volume sellers for space in top-tier warehouses with competitive SLAs.

What Is Retail Warehousing?

Retail warehousing refers to storing goods and fulfilling online orders from a warehouse space.

Retailers today have a new set of challenges as customer expectations for delivery are continually shaped by eCommerce. Today, 48% of customers want their delivery faster while 43% want it cheaper.

For instance, LS2, a motorcycle helmet brand, realized it was losing sales because its warehousing couldn’t support 1 to 2-day delivery. After optimizing their warehousing strategies, they quickly met customer expectations, boosting their growth to become one of America’s fastest-growing brands.

Most businesses today, however, don’t rely on retail as their single sales channel but take an omnichannel approach. A fully integrated and flexible warehousing solution will be able to meet both your retail warehousing and eCommerce warehousing needs through a single network and platform.

Why You Need Strategic Warehousing

Strategic warehousing is vital for both eCommerce and brick-and-mortar channels.

Strategic warehousing helps you meet the modern delivery expectations driven by the ‘Amazon Effect’ and meet 1–2-day shipping demands.

By strategically placing inventory across multiple locations nearest to your primary customer bases, you can offer nationwide 2-day shipping, a competitive advantage for growing businesses.

Strategic helps you meet customer demands without resorting to costly next-day air shipping and, ultimately, reduces overall costs by minimizing long-zone shipments.

Why Cowarehousing Might Be the Right Choice for You

Cowarehousing is an excellent option for fast-growing eCommerce businesses that need top-tier warehouse space and 3PLs without the constraints of traditional warehousing.

According to a forecast by McKinsey, there will be a warehouse space shortage of around 190 million over the next 3 years. As warehousing costs rise and labor markets change, this asset-light model gives you the flexibility to scale operations while shifting toward a more adaptable fulfillment strategy.

Cowarehousing typically involves a 4PL provider aggregating the inventory and order volumes from multiple merchants. This collective approach lets smaller merchants negotiate better rates and SLAs, which might otherwise be impossible.

Here are some key benefits of cowarehousing:

1. Guaranteed Labor

Finding reliable warehouse staff in a competitive labor market can be challenging for smaller merchants. Cowarehousing aggregates demand across multiple businesses, spreading out labor needs throughout the week and improving bargaining power for all involved.

It guarantees labor availability even when individual volumes might not justify it, which is particularly helpful during peak times from Saturday to Monday.

A merchant survey revealed that 36% of merchants spent more time managing labor in 2022, making guaranteed labor and simplified labor management a valuable benefit of cowarehousing.

2. Lower Costs

By sharing space and resources, merchants can reduce the operational costs of managing warehouse infrastructure and logistics. This model helps free up capital, allowing you to reinvest in growth and innovation rather than fixed costs.

3. Scalability

With cowarehousing, businesses can adjust their storage and labor use based on current needs without the long-term commitments required by traditional warehousing models. With the right Warehouse Management System (WMS), cowarehousing can be a smart solution that helps you proactively anticipate when it’s time to scale up.

4. Flexibility

Unlike conventional 3PL services, cowarehousing offers less stringent terms, allowing you to shift warehousing strategies quickly. This flexibility is vital to matching inventory distribution with geographic sales patterns, ensuring efficient operations across diverse markets.

5. Strategic Locations

With a distributed inventory model across strategic locations, fast-growing businesses can offer 1–2 days of shipping to 95–99% of the U.S. market. This network approach helps you meet customer expectations for quick and efficient delivery while avoiding the premium costs associated with faster shipping.

Warehousing for Amazon Fulfillment

Amazon has become a necessary component of any multichannel eCommerce business. The sheer amount of exposure and marketing tools provided by Amazon make it a great first step for businesses launching their marketplace sales channels.

Amazon’s fulfillment standards are among the toughest, and it continually adapts to shape customer expectations.

As a third-party seller, you have three main fulfillment options:

- Fulfillment by Amazon (FBA)

- Fulfillment by Merchant (FBM)

- Seller Fulfilled Prime (SFP)

While FBA is popular for Amazon-focused sellers, you might prefer FBM or SFP for greater inventory control and clearer warehouse operations visibility. These options allow you to tailor your warehousing strategies, whether aiming for nationwide 2-day delivery or targeting specific regions, ensuring your products meet Amazon’s Prime service levels efficiently. Our Amazon fulfillment guide helps you convert more top-of-funnel sales.

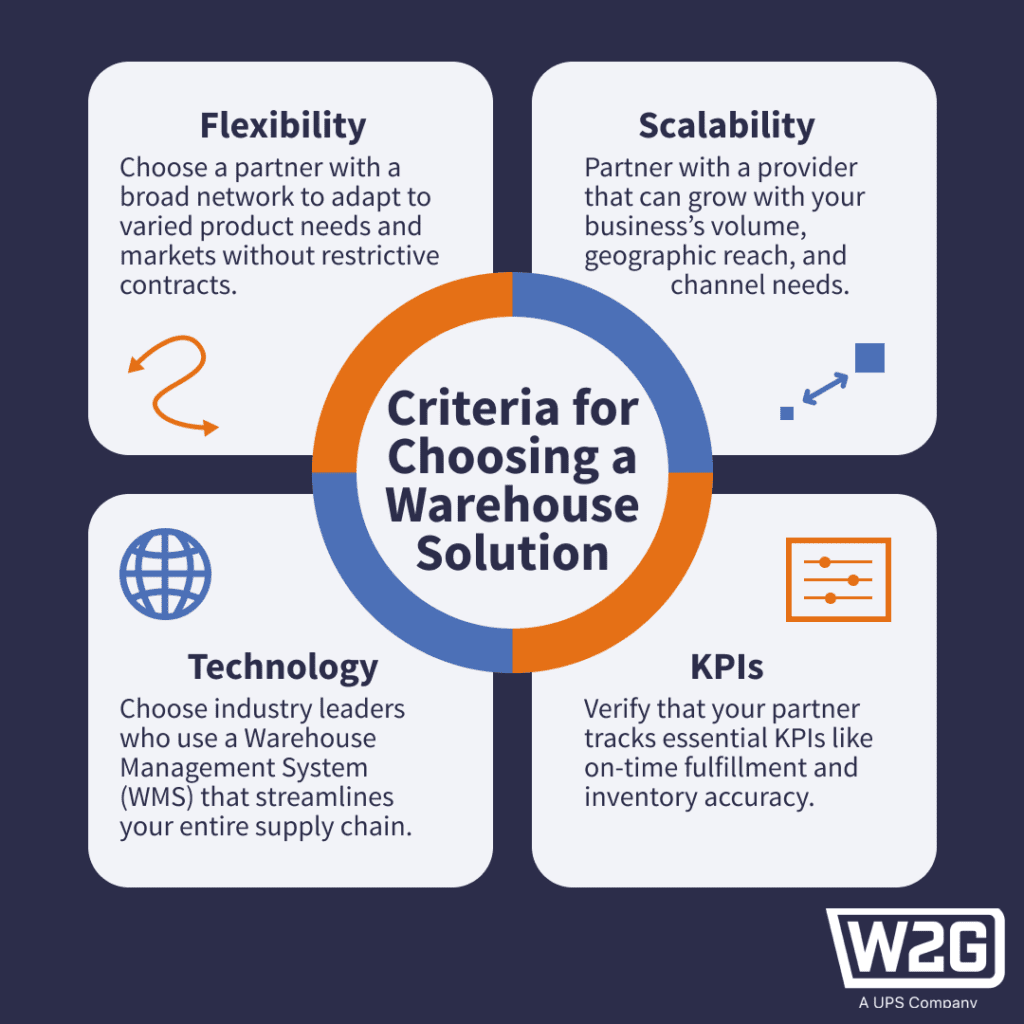

Criteria for Choosing a Warehouse Solution

When searching for the right warehouse for your business, it’s important to vet potential partners according to the right criteria. Prioritizing the following criteria will ensure you find a long-term partner to support your business goals.

Flexibility

Find a partner with a vast network to support various product needs and geographic markets. Don’t get roped into long-term contracts or AOV requirements. Instead, look for a partner that will support seasonal demand and will be able to pivot with you quickly to meet new opportunities in new geographies.

Scalability

Find a partner that can scale up with you in terms of volume, geographic footprint, and channel requirements to set your business up for long-term success.

Technology

The warehousing industry may not be known for its technological advances, but industry leaders use a WMS that simplifies your end-to-end supply chain management.

KPIs

Be sure to ask potential partners about Key Performance Indicators (KPIs) around on-time fulfillment, dock-to-stock time, damage rates, and inventory cycle counts.

Warehousing FAQs

Now that we’ve covered the main aspects of warehousing strategies and services, you may still have some specific questions or concerns.

To ensure we’ve addressed all of your questions, we’ve compiled a list of frequently asked questions that will provide you with additional clarity and help you make the right decision.

Why Does Warehousing Exist in a Supply Chain?

Warehousing keeps your inventory organized and ready to go as soon as a customer places an order. While some manufacturers use drop-shipping, this can lead to longer transit times and higher delivery costs. Strategic warehousing cuts down on these issues by storing products closer to your customers.

What Is Lean Warehousing?

Lean warehousing is a process of warehouse management that uses the fewest resources necessary without sacrificing efficiency or accuracy.

What Is the Process of Warehousing?

It starts when the merchant sends an Advance Shipment Notice (ASN) that details what’s coming to the warehouse. When the shipment arrives, warehouse staff check it against the ASN and store everything according to standard operating procedures (SOPs).

What Are the 4 Functions of Warehousing?

A warehouse’s job is to:

- Receive and store inventory

- Pick, pack, and ship orders

- Send out tracking information

- Maintain accurate inventory counts

What Are the Types of Warehouses?

Most warehouses fall into 4 categories:

- Full-service fulfillment centers (or distribution centers)

- Storage-only warehouses

- Third-party logistics (3PLs)

- On-demand warehouses

What Is the Main Function of a Warehouse?

The main function of a warehouse is to store inventory according to product needs (cold storage, humidity control, big and bulky, etc.) and keep accurate inventory counts to reduce the chance of inventory shrinkage or obsolescence.

Ware2Go’s Strategic Approach to Warehousing

Now that you’ve explored the various strategic warehousing services and understood the criteria for selecting a warehousing solution, it’s time to take the next step.

If you’d like more resources on supply chain, fulfillment, and warehousing strategies before making a decision, sign up for our newsletter.

But if you’re ready to choose a warehouse service provider, remember that Ware2Go combines a nationwide, distributed warehouse network with best-in-class fulfillment technology, including an integrated WMS to support multichannel sales and any transit mode.

Get closer to your customers with guaranteed two-day delivery when you use Ware2Go’s service.