Is your stock a treasure trove or a ticking time bomb?

Dead stock isn’t something companies should ignore, as it can take away a huge portion of your profits and result in inventory wastage. Discover the silent profit-drainer called dead stock that could have a hidden impact on your business’s bottom line.

Discover the blueprint for customer loyalty — check out our detailed guide on improving your fulfillment process to gain loyal customers.

This article will teach you what dead stock is and its five common causes.

You’ll learn how to reduce and avoid dead stock through strategic warehousing. Plus, you can use stock management to lower fixed costs, combat supply chain disruptions, and overcome current peak season challenges.

What Is Dead Stock, and What Does It Mean?

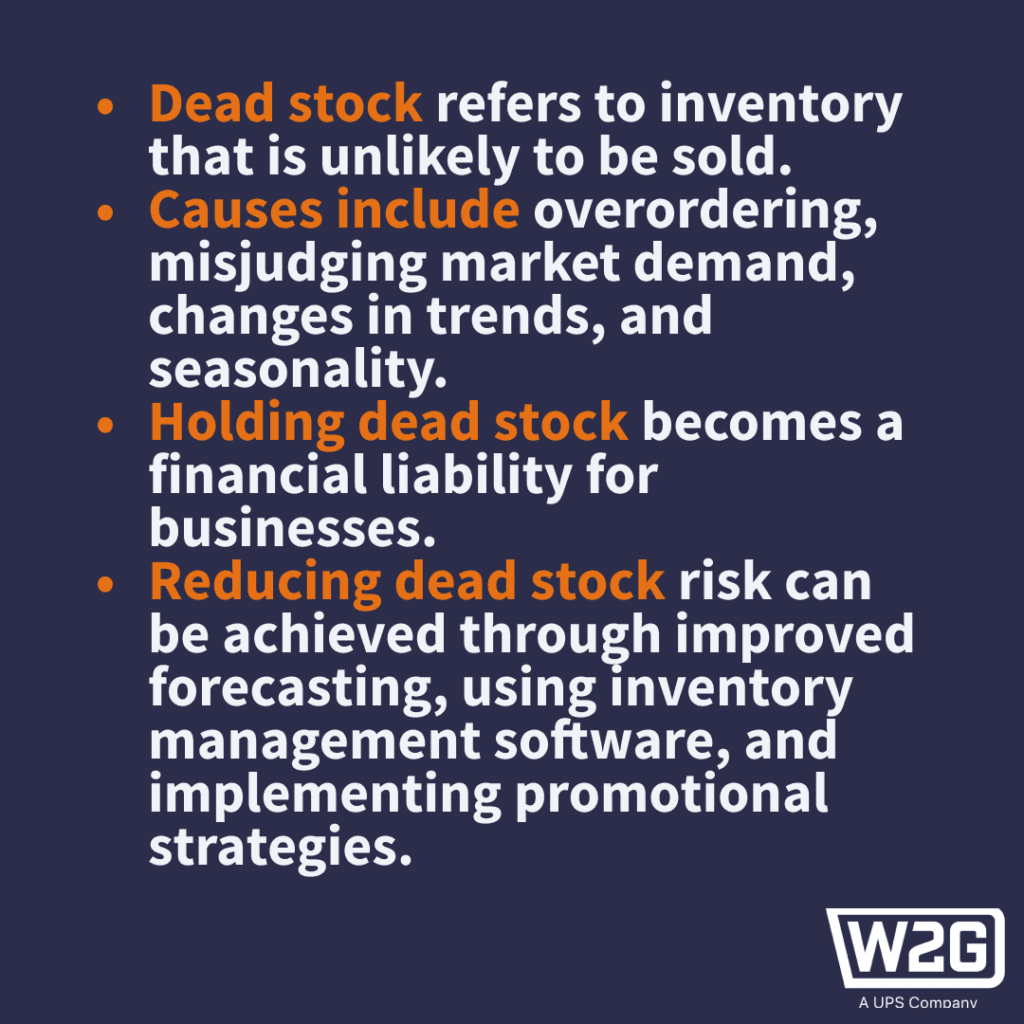

“Dead stock” refers to stock that’s no longer selling. Or it may be selling so slowly that it’s at risk of becoming obsolete or reaching the end of its product life cycle.

With the shrinkage of product life cycles due to modern-day technology and the competitive eCommerce landscape, stock obsolescence now happens much more frequently. It requires merchants to act even more quickly to prevent getting stuck with those slower-moving products.

To understand dead stock and stock obsolescence, it’s helpful to consider how excess stock accumulates and why it risks turning into dead stock.

Supply exceeding demand is often the cause of excess stock. This results in slow-moving stock that can incur expensive holding costs. While excess stock also involves holding large amounts of unsold stock, it usually represents a business opportunity to use a selling strategy. In contrast, dead stock represents a liability if companies don’t act fast on this excess stock.

Simply put, if a business lets stock sit idle for too long, they risk their stock becoming obsolete. The longer a product sits in storage, the higher the cost of holding it becomes. This turns excess stock from an opportunity into a liability for your business.

With increasing rates for warehouse storage, fast-growing brands need to be strategic about the types of stock they’re holding and where they choose to hold it. You must also know how much stock carry costs affect your bottom line.

Slow-moving stock or a high percentage of dead stock could cost you valuable inventory space, dragging down your profits and resulting in lost sales opportunities.

As a merchant, you’re not just absorbing dead stock’s purchasing and carrying costs. You also have to consider the opportunity cost of the space you could have used to store other products.

Deadstock vs. Dead Stock

Understanding the difference between these two very similar terms is essential in logistics and stock management.

Dead Stock refers to stock never sold to or used by consumers. So it sits idle in warehouses or storage areas.

On the other hand, in the fashion and resale industries, “deadstock” often denotes vintage or highly sought-after items that are new with tags. The main idea is that they’re unused but carry a certain rarity or desirability among collectors and enthusiasts.

While both terms sound alike, their implications and contexts within different sectors vary significantly.

Examples of Dead Stock

Due to technological shifts, legal regulations, consumer preferences, and seasonal demand, dead stock can arise from various sources.

Common examples include:

- Outdated Technology – Obsolete stock like floppy disks and VHS tapes became dead stock when CDs and digital storage options emerged.

- Perishable Goods – Foods and produce that exceed expiry dates without purchases contribute to dead stock.

- Legally Phased-Out Products – Changes in laws, such as bans on single-use plastics, can cause items like straws, bags, and cutlery to stop selling.

- Seasonal and Event-Specific Merchandise – Items specific to events or holidays, such as Super Bowl merchandise or Valentine’s Day candy, often become dead stock once the occasion ends.

Your products can turn into dead stock and cost your business money. That’s why you must learn to avoid dead stock and keep your business financially healthy and strategic with stock management.

Why Is Managing and Avoiding Dead Stock So Important?

What does dead stock mean when it comes to your stock management strategies?

Are the long-term storage costs of your stock more than the profit you’ll make when the product sells? If yes, your stock is starting to cost your business money at a potential loss.

Our supply chain expert, Matthew Reid, discusses on YouTube how businesses may be losing margins on the products they sell because they’re paying for more stock than they need:

“A proactive approach to managing slow-moving stock is to assess the product’s MSRP value and the margin the customer makes from that product. If that product doesn’t sell and the stock turns for that product start becoming anything from 2 to 3 stock turns per year or less, the customer is likely starting to pay more in storage costs than the product is worth.”

Ware2Go offers merchants valuable supply chain technology to analyze their stock. We provide commercial insights and recommend strategies to mitigate the costs of slow-moving SKUs.

Through proactive supply chain planning, our team of data scientists helps merchants improve their bottom line by mitigating the costs of surplus stock.

Watch Matthew Reid’s video below to learn how Ware2Go can help manage slow-moving SKUs and prevent dead stock.

The best way to alleviate the problem of dead stock is to pinpoint its causes and prevent dead stock from accumulating in the first place.

8 Common Causes of Dead Stock

Unfortunately, dead stock isn’t just caused by one issue. Here are the 8 common causes of dead stock that you must watch.

1. Inaccurate Demand Forecasting

Accurate demand forecasting plays an important role in avoiding unsold and excess stock. You want to prevent it from eventually turning into obsolete stock. After all, what is dead stock? It’s stock that isn’t moving quickly enough.

By anticipating consumer demand, analyzing industry trends, and matching your stock levels with marketing efforts, you can more effectively plan and manage your stock based on accurate demand forecasting models.

In addition, most businesses with strategic forecasting models also look at geographic demand to determine the best location to store their stock.

Using previous years’ sales history, geographic demand patterns, and current industry trends, you can make accurate forecasts, manage warehouse storage rates, and lower operating costs.

2. Poor stock Management

Inaccurate stock cycle counts, low visibility of order and fulfillment statuses, and outdated manual tracking processes can lead to stock shrinkage on one end of the spectrum or stock obsolescence on the other.

You can fix this by managing your stock digitally. You’ll receive a continuous flow of data, helping to visibly pinpoint slow-moving SKUs. This lets you respond quickly by implementing new selling strategies to reduce excess stock before the storage costs increase.

To quote our supply chain expert Matthew Reid from his YouTube video: “Understanding the velocity of SKUs for a product is important for a merchant. Because if that SKU is not selling, then at some point, it’s costing you more just to store that stock than it’s even worth.”

3. Low-Quality Products

Defective products and poor quality are also common causes of dead stock, and customers who aren’t satisfied with a product are more likely to return it.

Ensure that your stock of high-quality products pays off in the long run by analyzing, vetting, and market-testing new products. Partnering with reliable manufacturers will also decrease the chance of quality issues, provide a positive customer experience, and mitigate the risk of dead stock.

4. Inconsistent Ordering

Irregular ordering and supply chain delays can lead to backorders and accumulating unsellable products over time.

5. Over-Ordering

What does dead stock mean? Remember that it’s essentially excess stock. Buying more stock than you need can result from inaccurate demand forecasting or trying to take advantage of bulk discounts.

6. Poor Marketing Efforts

Only effective marketing can generate enough demand. Poor sales lead to unsold items becoming dead stock items.

7. Canceled Orders

What is dead stock’s relationship to canceled orders? Bulk cancellations or bespoke item rejections can leave you with stock that lacks immediate demand, contributing to dead stock.

8. Products with an Expiration Date

If you sell perishable items, some products will inevitably be unsold when they expire. However, there are ways to mitigate this.

Ware2Go’s FulfillmentVu software has a feature that will notify you when a product is approaching its expiration date. That way, you can run clearance sales or promotions to get it moving before it expires.

How to Avoid Future Dead Stock

It’s one thing to deal with dead stock once you already have it. It’s even better to prevent it from occurring in the first place. Here’s how:

Use Inventory Management Software

The best way to reduce the risks of stock obsolescence is by closely monitoring stock activity and performance. A streamlined stock management system helps you accurately track product performance. Plus, you can stay on top of opportunities to reduce losses from slow-moving products.

You might get tempted to purchase larger stock levels for better deals from bulk suppliers. A proper stock management system can help you accurately forecast and optimize stock purchasing costs by balancing bulk supplier discounts with stock carrying costs.

Ware2Go’s FulfillmentVu technology can help you effectively manage stock purchases and gain visibility into product performance.

Opt for Smaller Product Levels as a Sales Tactic

If you’re experiencing small product windows before items become dead stock, offering smaller runs emphasizing exclusivity can be an effective selling strategy.

Being strategic about which product is worth carrying in larger amounts will help to reduce stock surplus and the negative effects of dead stock. Consumers tend to place a higher value on items that feel more exclusive. So using a scarcity marketing tactic has become an effective strategy to transform lower stock levels into an advantage that helps drive consumer demand.

What is the cost of dead stock compared to running out of stock?

While you may risk losing a few sales if you sell out of an item, the cost of dead stock may be much higher than the profitability of holding more. However, with the right stock and SKU management system, merchants can accurately forecast sales and purchase the optimal amount of stock to meet demand.

Use Proper SKU Management

What does dead stock mean when it comes to handling your SKUs?

Managing SKUs is necessary for stock management. It allows you to measure the profitability of your products to decide how much stock you need to hold. Plus, you can determine how much storing that stock will cost.

As a result, businesses can accurately forecast demand and mitigate the costs of holding too much stock.

At Ware2Go, our stock management system integrates warehouse, order, and transportation system data. It also uses machine learning and AI to help analyze previous sales histories and seasonal patterns. This helps you accurately forecast demand and optimize stock purchases.

How to Deal with Dead Stock – Best Practices

Do you have some dead stock already sitting in your warehouse? Here are some potential ways of dealing with it:

Strategic Warehousing

If you’re already struggling with dead stock, consider strategic warehousing. In our context, this means choosing the most affordable warehouse to store slow-moving SKUs.

If your business has stock that isn’t moving, the best option is to relocate that stock strategically. Move it to a warehouse space that functions as a storage-only space. Or relocate it to the inner parts of the country where you can store it at lower rates.

Not all warehouse storage is equal. Partnering with a 3PL logistics service with a nationwide warehouse network helps you easily find the right warehouses and negotiate the most affordable rates to store dead stock.

Offer Promotions or a Discount

One of the most straightforward strategies to deal with aging or excess inventory is to offer a promotion. For example, “Buy one, get one free” promotions, bundles, free customer gifts with purchase, or a promotional discount.

This sales tactic may not be the most profitable. But it can help you recover the initial cost of the product and free up storage space for more profitable merchandise.

This technique is best when used early — when you notice slow-moving stock. You risk stock obsolescence by waiting too long to offer discounts or promotions on these products. Then, you may not sell the product at all, even at a discounted rate.

Donate Dead Stock for a Write-off on Taxes

What are dead stock’s implications when it comes to taxes?

Donating your dead stock to qualifying charities lets you claim legal donations in return for tax write-offs. It can be a great strategic tactic to cut your losses.

You may not be able to recover the full cost of manufacturing the goods, but this strategy often helps cut losses while also maintaining a positive public reputation.

For instance, a consumer survey found that 85% of consumers said it was important that a company support charitable causes.

Return Products to the Supplier

Negotiating returns of unsold stock in exchange for credit with suppliers can alleviate dead stock issues. Understanding your return policies before purchasing and maintaining good supplier relationships is important.

Consider Using a Liquidator

Liquidation, though often at a loss, can recuperate some of your investment, free up space, and improve your cash flow.

Dispose of It

You should only consider disposing of your products after you’ve exhausted all other avenues to recover some value.

These tips can help you handle dead stock better, turning a tough situation into a chance to save money. Working with companies like Ware2Go can make handling your products easier and cheaper, helping your business improve.

How 4PL Partners Can Help

You don’t have to work through your fulfillment and logistics challenges alone. Here are some ways that 3PL and 4PL services can help your fast-growing brand.

Negotiate Better SLAs and Lower Rates

It can be hard for fast-growing merchants to negotiate for lower rates and better service level agreements (SLAs.)

It can also be difficult for small merchants with lower volumes to get their stock into a top-tier warehouse.

Ware2Go makes this achievable by offering on-demand warehousing services. We negotiate with warehouses on your behalf to help you build a nationwide fulfillment network, streamline fulfillment, and lower take-away rates.

To summarize what Matthew Reid mentions in his video, Ware2Go constantly checks if we make the best decisions for our business partners’ supply chains. Our team of experts works hard to prevent extra costs and ensure our partners get the best service for their customers.

By aggregating multiple merchants’ average daily volume (ADV), we can negotiate better rates and help merchants of all sizes compete with high-volume sellers for this limited space.

On-Demand Warehousing to Help Scale Stock up or Down to Meet Demand

Ware2Go understands that small to mid-sized merchants need more flexibility during peak season. You’ve got to scale your warehouse storage up or down to accommodate the changing online inventory levels during holiday sales and seasonal demand.

You might wonder: What is dead stock’s connection to seasonality and demand spikes?

Smaller merchants have traditionally been forced into inflexible contracts related to the holiday peak season or another seasonal spike. These lock you into paying for unused storage during off-seasons or over-extending your internal resources to cover peaks without enough storage space.

Matthew Reid explains how Ware2Go can help merchants with this: “One thing we look at is stock balancing. Suppose we notice that ski jackets are selling well in Colorado, but the customer is storing ski jackets in Texas. In that case, we’d encourage them to move it up to Colorado, where you could offer a 1-to-2-day lead time on delivery to those customers.”

With Ware2Go’s on-demand warehousing model, merchants can pay only for the storage space and labor they use and flex these capacities up and down when needed.

Flexing your storage capacity up or down as needed helps seasonal sales to lower your year-round operating costs and makes your overall operation much more profitable.

Track Stock with a Stock Management Software

Ware2Go can help you implement our stock management software, FulfillmentVu, which integrates WMS, OMS, and TMS technology. It provides immediate insights into stock levels and fulfillment status.

Using this system, you can easily see which stock is selling well and which are underperforming in real time.

From there, you can access tools for strategic decision-making around stock allocation, marketing spending, and product repurchasing. This helps you mitigate costs in the supply chain and grow your bottom line.

For a full demo of our stock management software, reach out to one of our in-house experts.

Minimize Dead Stock with Ware2Go’s On-Demand Fulfillment and Warehousing

In this article, we’ve explored strategies to manage and reduce dead stock, including the importance of using stock management, strategic ordering, and marketing to prevent it.

Ware2Go’s on-demand fulfillment and warehousing solutions offer your growing eCommerce business a way to address these challenges, optimizing your stock levels and ensuring efficient use of resources.

Embrace Ware2Go’s expertise to streamline your operations and reduce dead stock in your business.