Many companies still use outdated, inefficient logistics systems. Their goods are scattered, fulfillment quality needs to be more consistent, and the average cost of distribution is high. The hub-and-spoke model offers a solution to these challenges.

This distribution model centralizes core logistics operations, leading to improved fulfillment quality and reduced distribution costs.

However, successfully establishing this distribution model requires careful planning and management — and, often, a fulfillment partner.

This article will discuss the hub-and-spoke distribution model and guide you on implementing one.

What Is the Hub-and-Spoke Model?

The hub-and-spoke model is any process that resembles the wheel of a bicycle, where paths (spokes) shoot out from a central location (the hub). In logistics, brands use hub-and-spoke distribution models to disperse inventory to multiple fulfillment centers or large box stores from a large distribution center or warehouse.

Hub and Spoke Examples

In the airline industry, it’s common to route flights from smaller market spokes through major hubs like Atlanta. For example, if you’re flying from Greenville, SC, to Tampa, FL, you’ll likely encounter a layover in Atlanta. Through this hub-and-spoke model, airlines can service more routes and maximize passenger loads.

Amazon sellers who use FBA for fulfillment are familiar with Amazon’s hub-and-spoke distribution model for fulfillment. Amazon distributes fulfillment centers across the country to help shorten time in transit and facilitate the fast delivery Prime customers expect.

Some business leaders also set up their offices based on the hub-and-spoke model. By having one central office where employees from numerous side offices report, employers gain access to a wider talent network, while employees have the flexibility to work in small groups and continue contributing to the organization’s strategic goals.

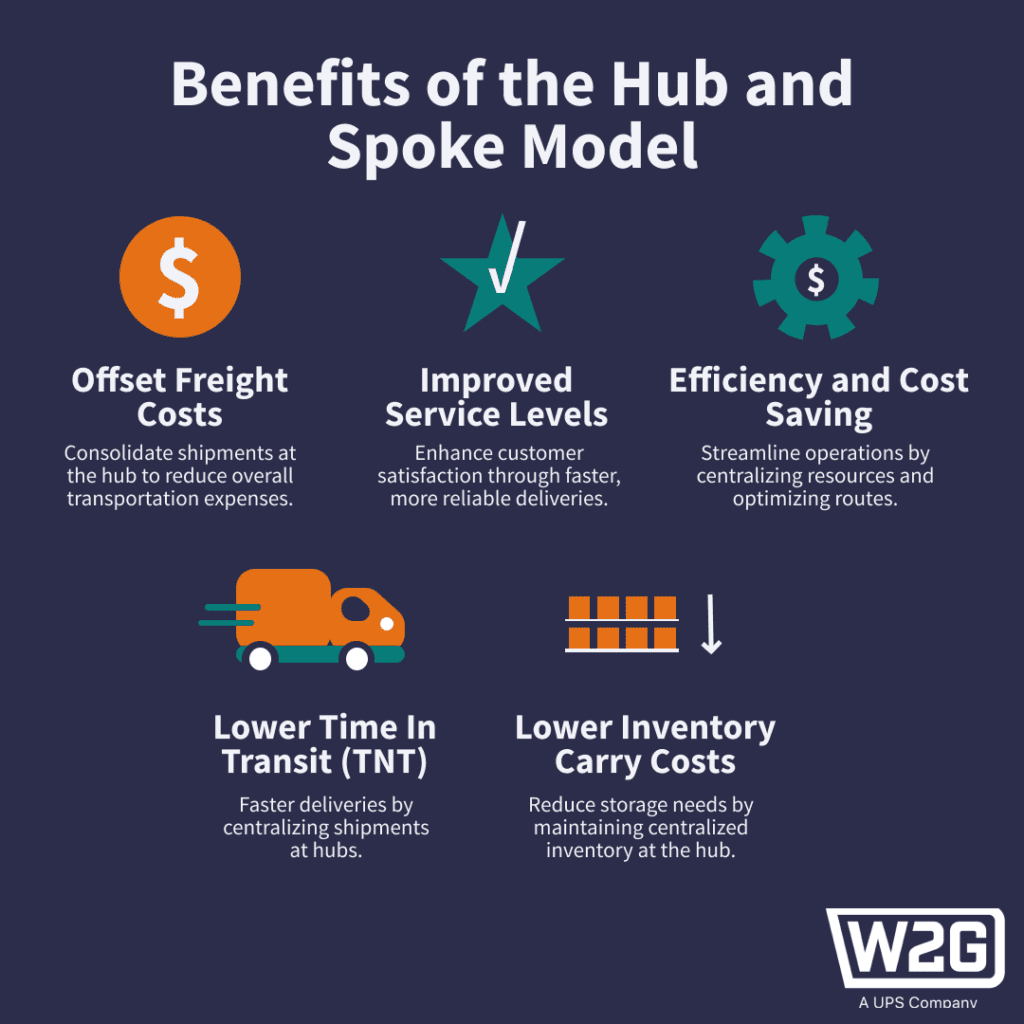

Benefits of the Hub-and-Spoke Model

When applied to inventory distribution, the hub-and-spoke model has numerous benefits. These include:

1. Lower Time in Transit (TNT)

The hub-and-spoke model lowers TNT at two phases of the supply chain.

a. Receiving Inventory From Manufacturers

In this model, the distribution center is located close to major and/or secondary ports. Once a container lands, it takes only a few hours to reach the distribution center.

b. Forwarding Inventory to Fulfillment Centers

Some warehousing partners like Ware2Go allow merchants to aggregate inventory, enabling you to distribute your inventory via full truckload (FTL) shipments rather than less-than-truckload (LTL) shipments. FTL shipments move faster through the network so your inventory can reach fulfillment centers quicker.

2. Improved Service Levels

This distribution model positions inventory as close as possible to consumers by quickly dispersing it to fulfillment centers, helping you meet fast delivery expectations.

Final mile costs are controlled with shorter distances to the consumer and costly long-zone shipments eliminated.

3. Offset Freight Costs

Since most SMBs ship LTL freight shipments, demand for LTL freight is high.

A strategic warehousing partner like Ware2Go helps merchants with geographic inventory distribution predictions. That way, merchants can negotiate FTL freight shipment rates to offset supply chain costs and realize higher margins.

4. Lower Inventory Carry Rates

Merchants that carry dead stock inventory can use this distribution model to keep their “C” and “D” movers at a large distribution center at a lower storage rate and their “A” and “B” movers in more strategic locations.

This helps avoid long-term storage rates that significantly erode margins.

5. Efficiency

This distribution model allows brands to handle core logistics operations from one place, leading to more efficiency.

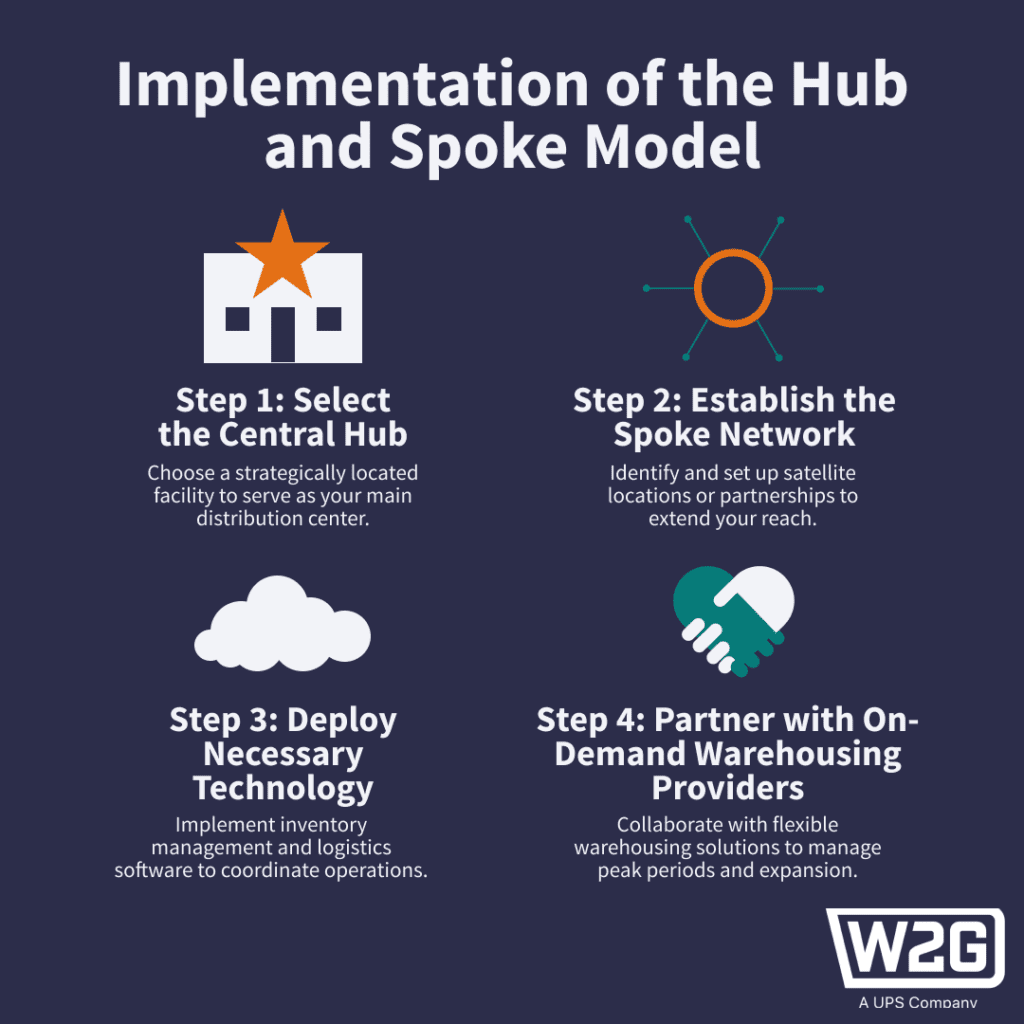

How to Implement the Hub-and-Spoke Model

Sold on the Hub and Spoke model and wish to improve your inventory distribution with it? Follow this four-step process to implement it.

1. Select the Central Hub

To choose a hub for centralizing core logistics operations, first list tasks in your current supply chain that would be more efficient if done in bulk. Then, identify a location where tasks can be most effectively performed. Consider:

- Accessibility to major transportation routes.

- Strategic position relative to your overall market coverage.

- Potential for future expansion.

- Availability of skilled labor in the area.

2. Establish the Spoke Network

Choose your spoke networks by analyzing specific regional market conditions, including geographic areas with high order volumes and customer demographics. Clearly define each chosen spoke’s role in its locality, such as fulfillment centers forwarding inventory to consumers’ homes or retail outlets servicing walk-in customers.

Analyze historical sales data and future growth projections to optimize spoke placement. Ensure each spoke has the capacity and capabilities to meet local demand effectively, aligning with its defined role and the area’s specific needs.

3. Deploy Necessary Technology

To ensure prompt dispersing of information and smooth collaboration between the hub and the spokes:

- Adopt and integrate necessary technology.

- Implement a robust warehouse management system to track inventory across all locations in real time.

- Invest in data analytics tools to forecast demand and optimize inventory allocation throughout the network.

4. Partner With On-Demand Warehousing Providers

To optimize your hub-and-spoke model, consider partnering with an on-demand warehousing provider like Ware2Go that helps brands maximize their supply network’s efficiency and customer satisfaction. Evaluate potential partners based on their technology integration capabilities and experience with hub-and-spoke models.

Establish clear performance metrics and communication protocols to improve coordination between your operations and the third-party provider. Ware2Go and similar services can help enhance your supply network’s efficiency and customer satisfaction.

Challenges and Limitations of the Hub-and-Spoke Model

While the hub-and-spoke model offers many benefits, it’s not without challenges. These include:

Dependency on the Central Hub

If the central hub, the powerhouse of this distribution model, encounters operational issues, the entire system will stop. This means that brands need central hubs with full-proof setups.

Initial Setup Costs

Setting up a hub with at least two spokes could cost thousands of dollars. This dissuades SMBs without huge budgets from benefiting from this cost-effective model.

Complexity in Management

Managing the hub-and-spoke model means managing numerous supply chain units, which can be challenging even for experienced supply chain managers.

Potential for Communication Bottlenecks

Unlike a point-to-point distribution model where there are no stops, the stops in the hub-and-spoke model often lead to potential communication delays or breaks.

This can hinder the efficient functioning of the model.

The Hub-and-Spoke Model for Brands of All Sizes

The hub-and-spoke distribution model enables large retailers to meet consumer expectations for 1–2-day delivery without inflating their fulfillment and delivery costs. However, with an on-demand warehousing partner like Ware2Go, brands of all sizes can realize the same efficiency in their supply chains.

Ware2Go: Optimize Your Distribution with a Hub and Spoke Network

The hub-and-spoke model provides a flexible, efficient distribution approach that can benefit businesses of all sizes. This approach provides clear benefits, such as reduced transit times, better service levels, and lower inventory costs, especially when partnering with solutions like ours at Ware2Go.

We offer on-demand fulfillment and warehousing solutions that simplify operations from warehousing to delivery. Our solutions help companies implement a hub-and-spoke model without managing multiple facilities.

This allows businesses to scale on their terms and compete with larger companies in delivery speed, often within a two-day window, improving customer satisfaction.

Contact us to sign up for our warehouse management services.