Just one extended disruption to production can cause companies to lose 30% to 50% of their earnings before interest, taxes, and depreciation. That’s why, though the drastic supply chain disruptions of the COVID-19 pandemic are behind us, supply chain resilience still remains a top priority for business owners.

In the post-pandemic world, geopolitical conflicts, inflation, and logistical challenges have made supply chain disruptions common. A 2023 McKinsey survey revealed that nearly all businesses, regardless of industry or location, have grappled with supply chain issues in the past year. Almost half said that supply chain disruptions caused major planning challenges.

So how can you build a resilient supply chain that meets customer expectations and propels your business forward in the face of disruption?

Let’s find out!

What Is a Resilient Supply Chain?

A resilient supply chain can endure disruptions and recover quickly, minimizing the impact of most disturbances on your production and delivery.

Resilient supply chains do more than just recover from damage; they adopt technology and modern processes to anticipate challenges to respond quickly to any risks or opportunities.

McKinsey found 3 components that ensured resilient supply chains:

- End-to-End Visibility – This means comprehensively viewing your entire supply chain using advanced tracking technologies to monitor all stages, namely, sourcing, manufacturing, warehousing, transportation, delivery, and returns, in real time.

- High-Quality Master Data – Ensure critical business data is accurate, consistent, and up-to-date. You must implement robust data management systems and perform regular audits. This helps with quick and effective decision-making during supply chain disruptions by providing accurate, real-time information.

- Effective Scenario Planning – This implies preparing for various future events and potential disruptions. Use predictive analytics tools and partner with 4PLs to develop flexible strategies to mitigate risks and ensure business continuity during supply chain disruptions.

7 Benefits of Supply Chain Resiliency

Supply chain resilience is the key to longevity in today’s market, where supply chain disruptions span industries. The pandemic may have thrown supply chain challenges into focus, but they have, in fact, always been part of doing business.

According to a McKinsey survey of 101 respondents across industries, sectors, and continents, almost half of the respondents said that they had to make major planning alterations due to supply chain disruptions.

Businesses with resilient supply chains succeeded through the most recent challenges, and fast-growing brands, in particular, have an opportunity to reimagine their supply chain as a growth driver in the face of market shifts and inevitable disruption.

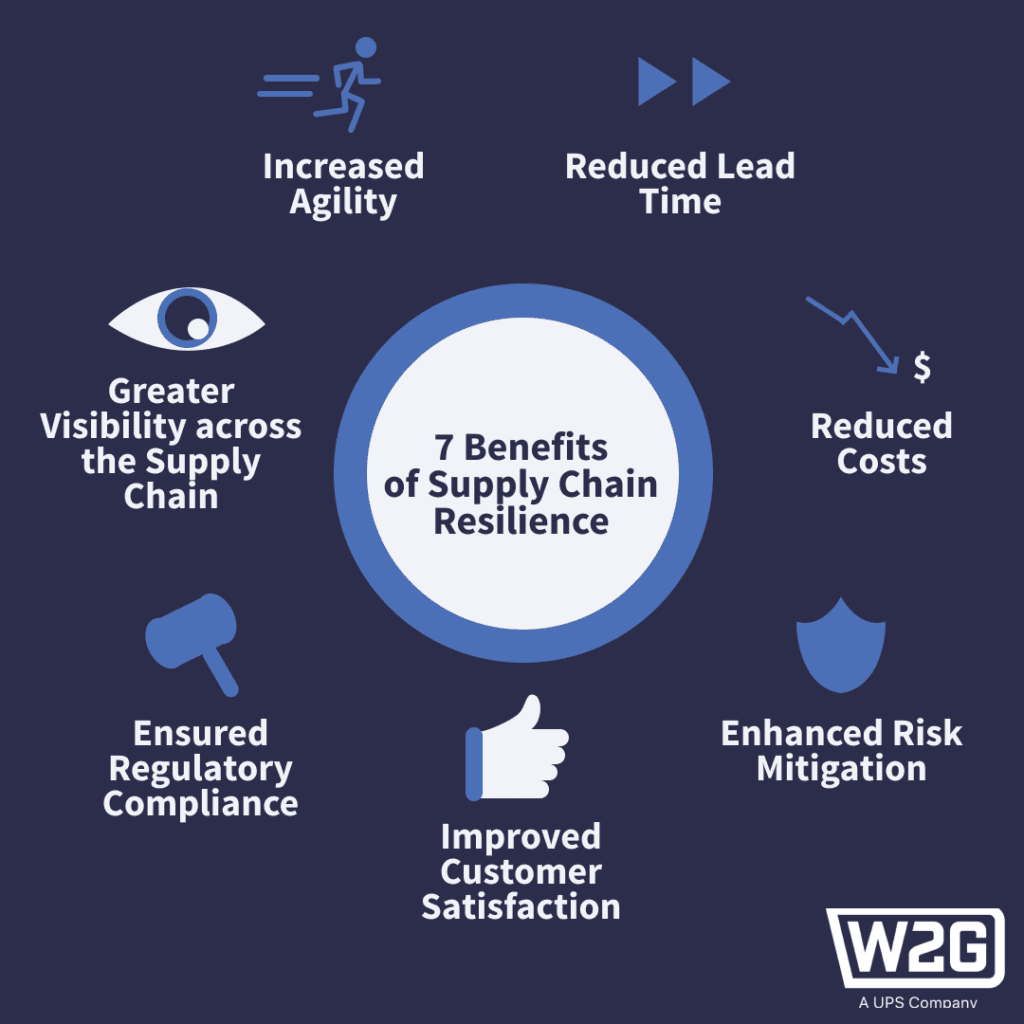

Here are the 7 key benefits of having a resilient supply chain:

- Increased Agility – Resilience helps you build more agile supply chains, quickly respond to customer demand or market changes, bounce back faster from supply interruptions, and maintain flexibility in your production and distribution processes.

- Reduced Lead Time – Streamlining inventory management and optimizing production schedules with a resilient supply chain can significantly limit the time between order placement and delivery. This improves responsiveness to customer needs and preferences, reduces inventory costs, and improves cash flow.

- Decreased Costs – Supply chain resiliency helps minimize the financial impact of unexpected disruptions by finding and eliminating waste, inefficiencies, and excess inventory. It further lets you avoid the high costs of stockouts, production delays, and lost sales.

- Enhanced Risk Mitigation – A resilient supply chain proactively identifies and assesses potential risks, develops contingency plans, and diversifies supplier networks, transportation routes, and production facilities.

- Improved Customer Satisfaction – With a reliable supply chain, businesses can consistently meet customer expectations while quickly responding to changing customer preferences, ensuring that buyers always have the right products in the right place at the right time.

- Ensured Regulatory Compliance – Staying up-to-date with evolving industry standards and regulations is essential for building supply chain resiliency. Maintaining proper documentation and certifications helps businesses avoid costly penalties, fines, or legal consequences.

- Greater Visibility across the Supply Chain – Resilient supply chains provide real-time insights into inventory levels, production status, and shipment tracking. With greater visibility, you can quickly identify potential challenges, foresee future disruptions, and proactively mitigate their impact.

Top 6 Strategies for Creating Supply Chain Resilience

Ahead, we’ll outline the top 6 supply chain resilience strategies and share real-life case studies of companies who applied these.

1. Find Asset-Light Solutions

Asset-light logistics providers manage supply chain operations without owning physical assets, such as trucks, trailers, warehouses, and distribution centers. Instead, they use their expertise and network to negotiate contracts with carriers, warehouses, and other logistics providers on their clients’ behalf.

This allows them to offer flexible, cost-effective, and tailored solutions. Depending on market changes, they can also help scale your logistics operations up or down quickly, thus building a more resilient supply chain.

Choosing an asset-light supply chain solution frees up capital for you to make quick decisions around product development, customer experience, or marketing spending.

Children’s furniture brand ECR4Kids had a fully in-house fulfillment solution. They owned and operated 3 warehouses in the U.S., which served their primarily business-to-business (B2B) customers well. However, when they branched into direct-to-consumer (D2C) sales, they found that their in-house solution was unable to keep up with the demands of marketplace sales, so they outsourced their D2C fulfillment to Ware2Go.

ECR4Kids picked Ware2Go for their on-demand approach and received a flexible and comprehensive solution allowing them to:

- Adjust their use of Ware2Go’s based on their needs

- Provide fast, 1–2-day delivery to their customers

- Get full support for all their warehousing and fulfillment tasks

After outsourcing a single portion of their business, they saw how much capital and internal bandwidth a fully outsourced solution could free up for their company. They quickly decided to exit their owned warehouses and pivot all of their fulfillment to their warehousing partner.

Ultimately, their decision to outsource fulfillment to Ware2Go saved them nearly $700,000 per year in warehousing and fulfillment costs.

2. Prioritize Flexibility

Flexibility is the key to supply chain resiliency, and it can be built into every link of the supply chain. It relies on strong partnerships and scalable technology.

Warehouse Agreement Flexibility

Long-term storage agreements with guaranteed volume leave you 2 options:

- Limit sales potential based on the storage space you can afford

- Lock in rates at peak volume and diminish the profitability of sales

A flexible warehousing and fulfillment partner allows you to scale your warehouse space and labor based on demand, offering you more supply chain resilience.

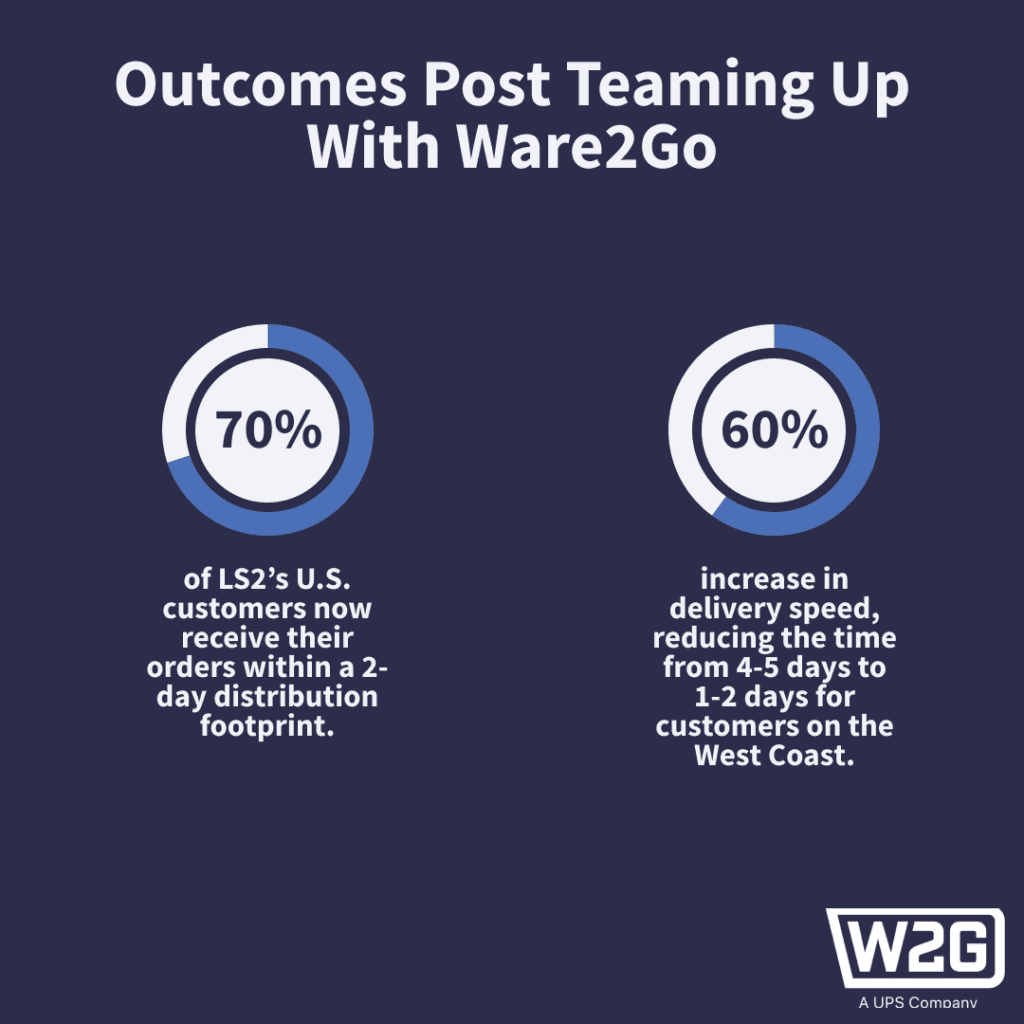

LS2 Helmets, America’s fastest-growing motorcycle helmet brand, saw the cost of expanding their traditional fulfillment solution into new markets was prohibiting their growth. As they researched their options, they found that a partnership with an on-demand warehousing partner like Ware2Go would allow them to pay only for the space they needed when they needed it.

This flexibility mitigated the risk of expanding into new markets and fueled their growth. As a result, LS2 experienced a 60% growth in delivery speed, delivering 70% of its U.S. customers within 2 days of ordering.

3. Transportation Flexibility

Consumers have endless options when it comes to where and how they shop. Their preferences have swung from brick and mortar to eCommerce and back again as shoppers navigate their ever-growing options.

Even B2B purchasing has changed as more corporate buyers shift to eCommerce channels. In fact, McKinsey reports, “Not only are corporate buyers open to eCommerce, ⅔ now rely on digital and remote channels throughout their purchasing journey.”

These purchasing pattern shifts mean merchants can no longer segment their supply chain between B2B and D2C channels. A resilient supply chain will have the flexibility to fulfill all order types from multiple sales channels through a single platform — seamlessly pivoting between less-than-truckload (LTL), full-truckload (FTL), and small parcels as needed.

LTL is ideal for smaller shipments that don’t require a full truck, and it allows consolidation of orders from multiple customers. FTL is suitable for larger shipments that fill an entire truck, and it provides faster transit times and minimizes handling. Small Parcel is perfect for individual consumer orders and offers cost-effective shipping for lightweight packages.

Using a single platform that seamlessly integrates these transport options, fast-growing businesses can construct a more resilient supply chain.

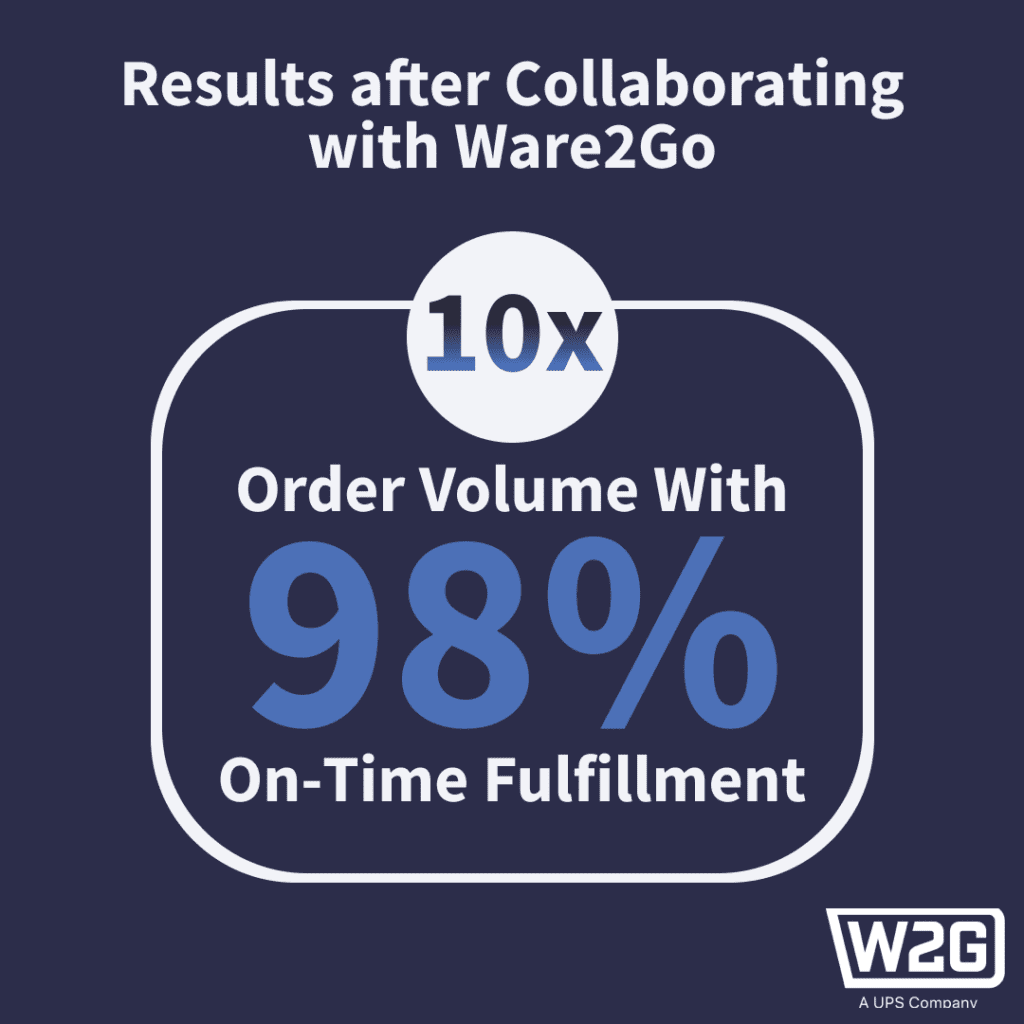

Athletic recovery drink, O2, credits their flexible fulfillment solution supported by Ware2Go with their ability to pivot and thrive during COVID-19 shutdowns. Prior to the pandemic, their primary sales channel was retail sales in gyms. When gyms were shut down in 2020, that sales channel was effectively closed. They had to act quickly to direct customers to their online channels.

Ware2Go stepped up to the challenge by revamping O2’s entire fulfillment operations. They fulfilled 98% of their new direct-to-consumer orders on time, and 99.5% of customers received orders within a 1–2-day delivery footprint.

Because they had a flexible fulfillment solution offered by Ware2Go, they could seamlessly pivot from B2B to D2C order fulfillment. The abrupt change in their order profile did not slow down their operations.

In fact, when many businesses struggled to stay afloat, O2 grew their business by 5x overall.

4. Create Diversity

Having a diverse network of partners gives you peace of mind that if one channel is shuttered, another one can be switched on without missing a beat.

Supplier Diversity

For years, many merchants have relied on single manufacturers, but the regular factory shutdowns in China and Vietnam during the pandemic highlight the need for a multi-threaded approach to procurement. For some merchants, that may mean negotiating contracts with multiple overseas suppliers. For others, it could mean nearshoring (we’ll discuss nearshoring shortly).

Network Diversity

Freight delays and port congestion most recently highlighted the need for alternate shipping lanes and ports of entry. Network diversity can even be beneficial at a warehouse level. Inclement weather, mass power outages, or other service disruptions can shut down entire warehouses and regions. Having a distributed warehousing network allows you to re-direct orders if any single warehouse is shut down.

5. Focus on Inventory Management

Inventory management tracks a company’s stock of goods, including raw materials, work-in-progress, and finished products. It involves balancing the right amount of inventory to fulfill customer needs while reducing costs and increasing profitability.

During the pandemic, many retailers shifted from a Just in Time (JIT) procurement model to a Just in Case (JIC) model due to supply chain shortages. However, this led to excess inventory and deep discounts for some major retailers, like Target.

A resilient supply chain is one that prioritizes sales velocity and profitability in inventory management. For many merchants, this means narrowing down their SKU catalog to focus on the top revenue drivers for their business. This helps build resilience into the supply chain by:

- Increasing Margins – Removing slow-moving SKUs increases profitability and promotes sustainable growth for your business.

- Decreasing Storage Costs – Fewer SKUs take up less space in the warehouse, so you can carry your best sellers in higher volumes.

- Simplifying Inventory Distribution – A smaller warehouse footprint makes it easier to distribute inventory to lower your final mile time in transit (TNT) and meet customer expectations for delivery.

6. Consider Nearshoring

Nearshoring involves companies shifting offshore operations to neighboring countries. While factory shutdowns in China and other markets during the pandemic led to a growth in nearshoring, it actually gained significant momentum in 2023, with Mexico overtaking China as the U.S.’s top trading partner and maintaining the position even in Q1 2024.

Here’s how nearshoring helps you build a resilient supply chain:

- Reduces lead times by moving production and sourcing closer to where products are sold

- Increases flexibility and faster reaction to changing customer needs

- Allows for better tracking of production progress, ensuring quality standards are met

- Assists in effective inventory management through increased visibility

- Helps with forecasting demand, controlling inventory, and quickly spotting critical supply chain vulnerabilities

- Offers financial benefits such as lower transportation costs, reduced customs fees, and potentially lower labor expenses in nearby locations

- Manages supply chain risks by lowering exposure to delays in long-distance shipping, transport bottlenecks, and uncertainties related to geopolitical issues

6. Build Inventory Buffers

Having safety stock is a simple way to make your supply chain more resilient. If something disrupts your supply chain or customer demand suddenly increases, you’ll have backup stock to keep things running smoothly.

But holding extra inventory can be challenging. It costs money to buy and store, so you need to manage it well. You also have to figure out the right amount to keep on hand. Too much ties up cash and cuts into profits, while too little might not be enough to avoid running out of stock.

To make buffer inventory work in your favor, you need end-to-end supply chain visibility so you can make smart choices about how much extra stock to keep. Using supply chain technologies like virtual inventory and predictive forecasting, you can build more supply chain resiliency even during unexpected events.

Ware2Go’s digital supply chain solution integrates with all sales channels and offers real-time inventory visibility and business intelligence tools to help with your sourcing and inventory planning.

Supply Chain Resilience FAQs

Now that you’re confident about the strategies to build supply chain resilience, let’s answer some common questions you might still have.

What Is the Biggest Threat to Supply Chain Resilience?

The biggest threat to supply chain resilience can vary depending on numerous factors such as industry, geography, and the specific characteristics of the supply chain itself. However, some common threats include natural disasters, geopolitical instability, cyber-attacks, pandemics, and disruptions in transportation or logistics networks.

What Is Supply Chain Resilience?

Supply chain resilience refers to the ability of a supply chain to anticipate, prepare for, respond to, and recover from disruptions in order to maintain or quickly restore normal operations. It involves building flexibility, redundancy, and agility into the supply chain to adapt to unforeseen circumstances without significant disruptions to the flow of goods and services.

How Can You Measure Supply Chain Resilience?

Supply chain resilience can be measured using various key performance indicators (KPIs) that assess different aspects of resilience. Some common metrics include:

- Time to recover from disruptions

- Inventory levels and turnover rates

- Supplier performance and reliability

- Lead times for procurement and production

- Financial impacts of disruptions

- Customer satisfaction during disruptions

By tracking these metrics and analyzing performance over time, companies can gauge their supply chain resilience and identify areas for improvement.

Why Is Supply Chain Resilience Important?

Supply chain resilience is crucial for ensuring business continuity, reducing operational risks, and maintaining customer satisfaction. It allows companies to withstand and recover from disruptions more effectively, minimizing the impact on production, distribution, and revenue.

Supply Chain Resilience Simplified with Ware2Go

Ware2Go, a UPS company, is simplifying the end-to-end supply chain to enable merchants of all sizes to compete and grow in the face of supply chain disruptions. A distributed warehouse network, supported by best-in-class supply chain technology and freight services, helps merchants transform their supply chain into a growth driver for their business.

To know more about how we can help you, talk to our team.