Your customers want freedom of choice — not just in the goods or services they buy, but also in how those purchases are completed and delivered. According to CapitalOne researchers, 73% of consumers identify as omnichannel shoppers. That means they flip back and forth between where they buy and expect a range of delivery options.

Consumer expectations are high. There’s demand for retail stores to offer same-day shipping, next-day shipping, scheduled delivery, multiple store pick-up locations — you name it. What’s more, you’re expected to create a consistent shopping experience for customers regardless of the fulfillment channel they select.

As a result, companies that offer three or more fulfillment options experience 3.5 times better engagement with their customers.

Want your business to realize higher engagement rates? It might be time to adopt an omnichannel fulfillment strategy.

Read on to find out what omnichannel fulfillment is, learn about the benefits of taking on an omnichannel approach, and get proven tips on how to implement an omnichannel fulfillment strategy for your business.

What Is Omnichannel Fulfillment?

Omnichannel fulfillment is a logistics strategy in which businesses use multiple channels and fulfillment options to ensure a seamless and flexible customer experience.

By taking on an omnichannel approach, businesses can integrate each of their sales and fulfillment channels into one system. That means customers gain a unified experience in which they get to shop, purchase, and receive products seamlessly via their desired method.

An omnichannel model is built on four core features:

- Unified inventory management: Omnichannel retailers use a centralized management system to guarantee a single source of truth to guarantee inventory accuracy.

- Multiple fulfillment options: Omnichannel operations rely on a range of flexible fulfillment options for customers — whether it’s click-and-collect, same-day delivery, next-day delivery, or anything in between.

- Channel integration: There must be seamless connection and coordination between all of your sales channels to provide a consistent experience across all shopping and fulfillment options.

- Real-time data synchronization: Efficient order fulfillment depends on real-time inventory data to ensure that everyone in supply chain operations has constant inventory visibility.

By combining these components into one centralized strategy, retailers can take their fulfillment game to the next level, leaving behind disjointed systems to create a more reliable shopping experience that builds customer loyalty.

How Is Omnichannel Fulfillment Different from Multi-channel Fulfillment?

Some people use the terms “omnichannel fulfillment” and “multi-channel fulfillment” interchangeably. But there’s a fundamental difference between the two: integration.

A multi-channel fulfillment strategy helps a business establish a presence across various platforms. However, those platforms aren’t necessarily connected.

For example, let’s say you run a small craft business. As part of a multi-channel fulfillment strategy, you might supplement in-person sales at your brick-and-mortar stores by using Fulfillment by Amazon (FBA). Although you’re using multiple fulfillment options, your systems won’t be unified — leading to two very different customer journeys.

By contrast, omnichannel fulfillment helps businesses create a connected and cohesive experience across multiple channels.

Maybe you run a mid-sized clothing retailer with 50 physical store locations, an eCommerce store, and a mobile shopping app. To manage those channels using an omnichannel fulfillment strategy, you’d want to deploy a centralized inventory system to connect third-party logistics providers, different warehouse locations, and retail stores.

In doing so, you’d create complete visibility across all operations — guaranteeing a reliable shopping experience regardless of the fulfillment option a customer selects.

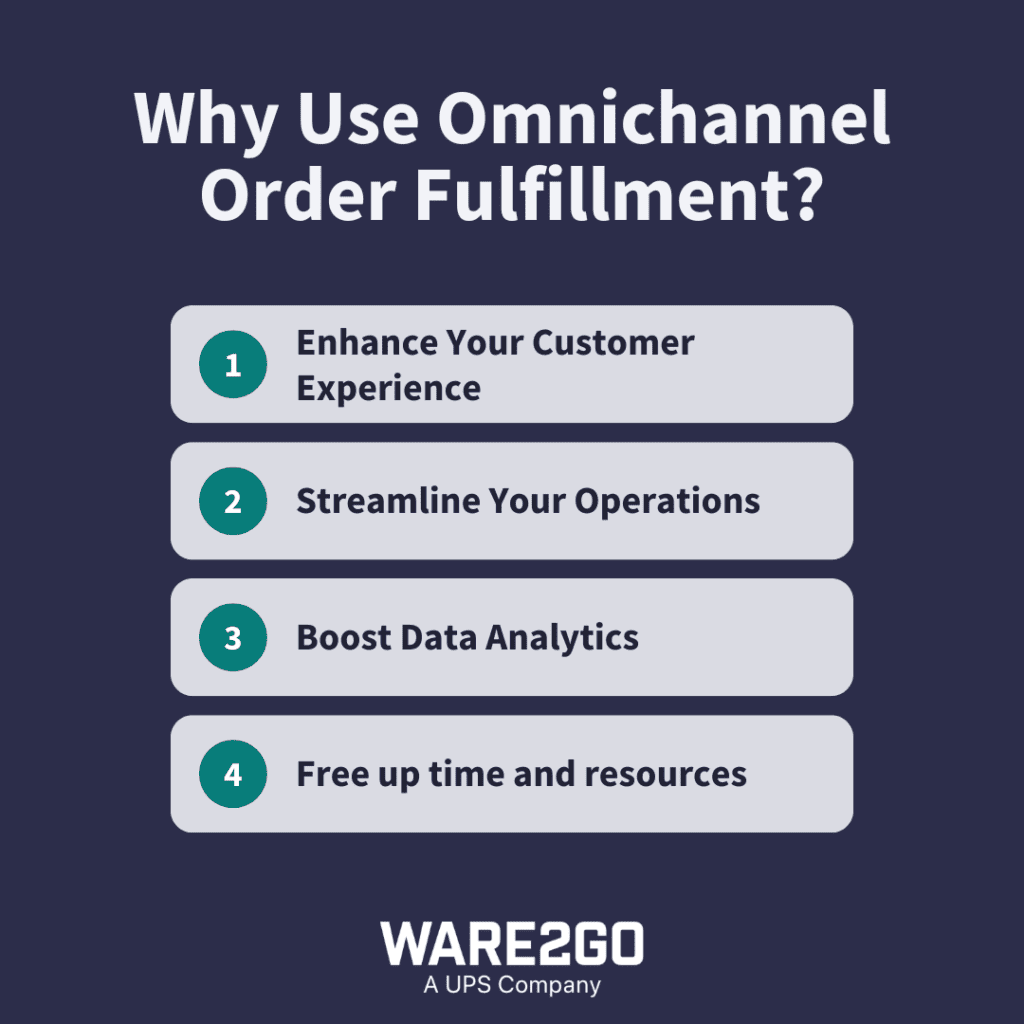

Why Use Omnichannel Order Fulfillment?

Most customers identify as omnichannel shoppers, and that should be reason enough for you to adopt an omnichannel approach.

But you can expect to leverage multiple benefits by centralizing your fulfillment operations — and a couple of those benefits just might surprise you.

Enhance Your Customer Experience

By providing more shipping options and uniting those options across every sales channel, you’re creating customer convenience. They can shop preferred channels and still have access to all of your fulfillment options.

This creates a unified shopping experience across all of your channels and allows customers to select the fulfillment method that best suits their needs no matter how they like to shop.

Translation: people are getting what they want, how they want it, and they’re getting it faster. That means fewer frustrated customers and more 5-star reviews.

Streamline Your Operations

Omnichannel fulfillment pools inventory from all locations to minimize issues like stockouts or overstock.

This optimized inventory utilization leads to cost savings. There’s no inventory wasting space, and you can reduce transportation costs and your delivery times by integrating new fulfillment options as part of your omnichannel approach.

Then there’s adaptability. Your business will be better poised to respond to spikes in future consumer demand. This is because you’ll have multiple fulfillment strategies at your disposal to meet your requirements — making it easier to scale operations at pace.

Boost Data Analytics

You’ll be able to start tracking customer behavior and use data to build a better picture of how customers interact across channels so you can optimize marketing and create bespoke offers.

You’ll also notice a night-and-day difference in terms of inventory visibility. Using central data systems means you’ve got real-time visibility into stock levels. This reduces markdowns and lets you optimize your replenishment strategies.

Finally, great data means less risk. Using inventory and customer data, you can optimize fulfillment across locations to reduce the risk of supply chain disruption. That means you and your fulfillment partners are always ready for what comes your way.

Free up Time and Resources

Keeping track of inventory is a drain on time and staffing if sales channels have different touchpoints. By contrast, an omnichannel approach integrates inventory management across all channels to support real-time inventory visibility — freeing up your time to focus on higher-value tasks.

A centralized system also supports automatic order routing, automatically directing orders to the most efficient fulfillment location. That reduces the amount of time you spend manually processing and assigning orders.

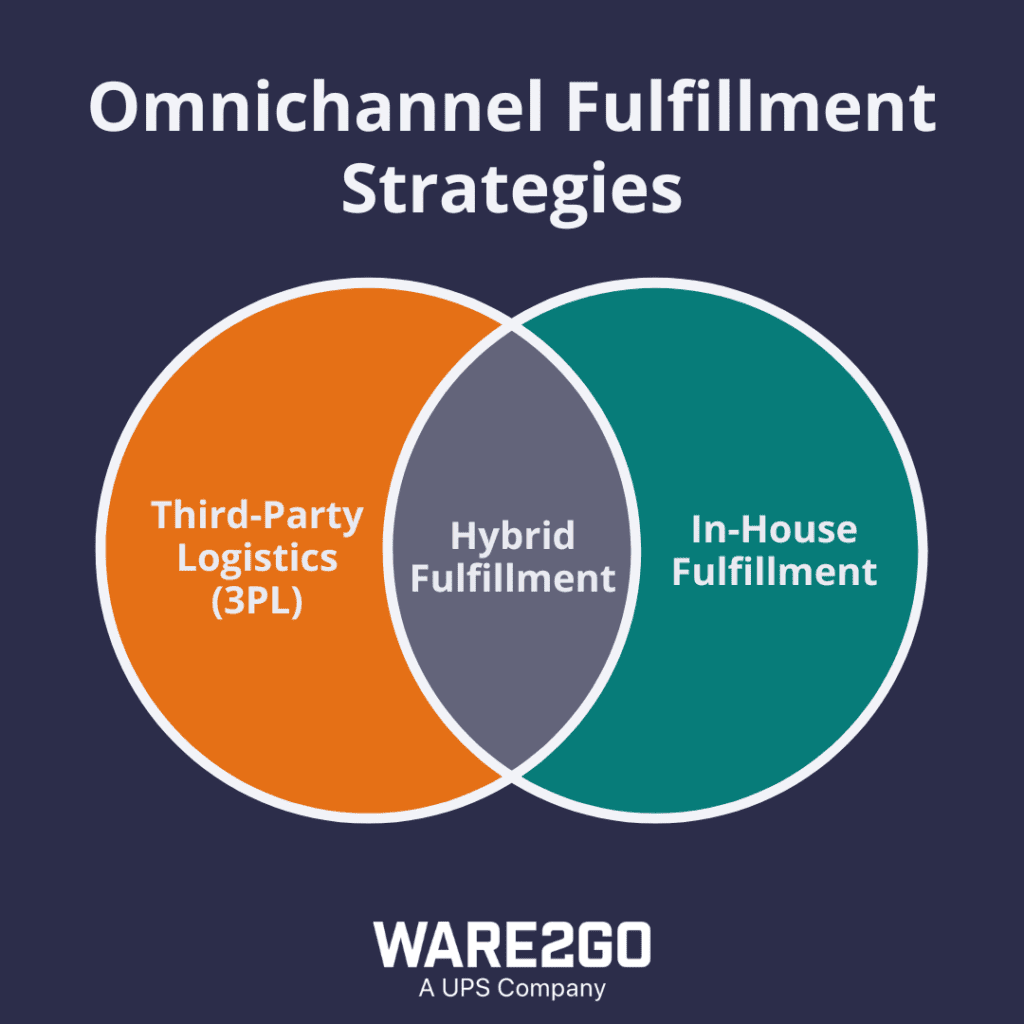

Omnichannel Fulfillment Strategies

If you’re looking at the benefits of an omnichannel strategy and wondering how it might look at your business, there are a few different options available to you: outsourced fulfillment, in-house fulfillment, or hybrid fulfillment.

To help give you an idea of what might work best for you, let’s take a look at the pros and cons of each fulfillment strategy.

Outsourced Fulfillment

By partnering with a third-party logistics provider (3PL), retailers can take advantage of direct integrations those providers already have in place.

Your business can utilize your 3PL’s network of distribution centers, access to eCommerce platforms or online marketplaces to offer a unified experience via multiple sales platforms and fast shipping via a multitude of delivery methods.

The key benefits of outsourced fulfillment include:

- Cost savings: Third-party logistics providers already have expansive networks. That means minimal infrastructure investment for your business to create an economy of scale.

- Industrial expertise: 3PLs live and breathe logistics. They’ll already have optimized workflows, advanced operational systems, and proprietary tech to support your fulfillment needs.

- Scalability: By partnering with 3PLs, you can easily scale up or scale back your operations based on your business needs.

As a result, you’ll gain the ability to manage your inventory and orders without having to focus on execution — freeing up your time to focus on other elements of growing your business.

But because you’re letting go of some control over your operations, it’s vital that you choose a flexible outsourcing provider that can provide you with the options and capability you require to meet your customer demands.

Ware2Go offers unique plug-and-play supply chain technology that allows you to add any available fulfillment center and choose between hundreds of eCommerce platforms, marketplaces, and order management systems to create your own custom fulfillment network that leverages UPS’s extensive coverage.

Plus, Ware2Go’s advanced FulfillmentVu platform seamlessly integrates with your existing tech stack — placing you in the driver’s seat at all times and ensuring you’ve got constant oversight of your customer experience and branding.

In-house Fulfillment

Another omnichannel approach you could opt for is an in-house strategy. When you manage your omnichannel fulfillment in-house, that means you’re responsible for everything: inventory management, order processing, packing, shipping, and returns.

When managed in-house, a company needs to own and operate its own warehouses, technology, and logistics teams. The key benefits of this approach are:

- More control: You’re always responsible for your own inventory and fulfillment processes, and you can change anything whenever you want to.

- Customization: By bringing everything in-house, you can mold the customer experience in any way you want.

- Faster decision-making: Without anyone else in your fulfillment chain, you can pivot instantly without relying on external partners.

These pros can also flip into cons for a lot of retailers.

An in-house approach requires significant investment in infrastructure, staff, and technology. And as you add more fulfillment channels, operations get more complicated to manage.

The buck stops with you, and you alone are responsible for managing peak demand, making tricky decisions, and mapping out customer journeys. That’s why so many business owners prefer an outsourced approach or a hybrid fulfillment approach.

Hybrid Fulfillment

Hybrid omnichannel fulfillment combines various elements of outsourced fulfillment and in-house fulfillment. This enables a business to maintain full control of certain fulfillment operations internally while outsourcing other operations to 3PL experts.

The core benefits of hybrid include:

- Risk mitigation: Because responsibilities are diversified, your business can be more insulated from supply chain disruption.

- Scalability: A hybrid approach enables you to expand fulfillment without major investment.

- Flexibility: Hybrid fulfillment balances internal management with external support – giving you the ability to pivot for peak demand.

A hybrid approach can increase the complexity of your operations, as it requires extensive coordination to ensure seamless alignment. But for some businesses this may be the best option for omnichannel management.

For example, let’s say your business uses in-house fulfillment for high-margin products, key markets, or specific sales channels. This might include handling orders from flagship brick-and-mortar stores, buy online, pick-up in-store (BOPIS), or particularly fragile items.

Meanwhile, you might want to partner with a 3PL to manage the “squeaky wheels” that don’t easily fit in with your normal operations. A partner like Ware2Go can step in to take on more complicated stock keeping units (SKUs) that have special storage requirements, kitting projects, or ocean freight.

Or you could choose to manage specific channels yourself and have your integrated partner manage others.

For example, you may want to manage all orders that come in through your website but could use Ware2Go’s over 300 plug-and-play integrations and exclusive partnerships to fulfill orders on platforms like Amazon Prime, Walmart+, Target, Macy’s, and TikTok.

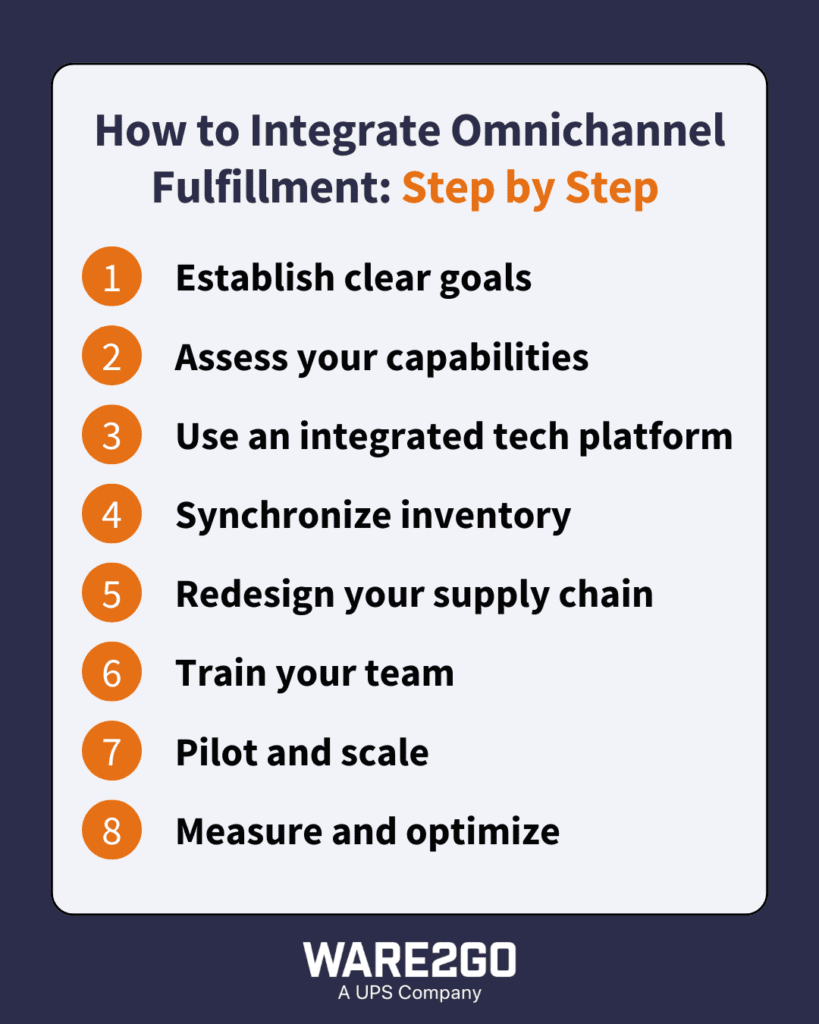

How to Integrate Omnichannel Fulfillment: Step by Step

Regardless of the omnichannel strategy you adopt, the process of deploying that approach is relatively simple.

To help you get started, let’s break it down step-by-step:

- Establish clear goals: Define specific goals for implementing omnichannel fulfillment. For example, maybe you want to reduce delivery times, improve customer satisfaction, or increase operational efficiency.

- Assess your capabilities: Next, evaluate your current inventory management system, analyze infrastructure, and assess whether your tech stack can handle omnichannel workflows and reverse logistics.

- Adopt an integrated technology platform: Invest in an order management system, warehouse management system, and analytics to predict demand, optimize inventory placement, and monitor performance metrics. Alternatively, ensure you select an outsourcing partner like Ware2Go that can provide a simple tech solution to help you hit the ground running.

- Synchronize inventory: Implement real-time inventory tracking and enable “single view of inventory” for real-time updates on availability.

- Redesign your supply chain: Develop new workflows to support alternative channels like ship-from-store, BOPIS, and micro-fulfillment.

- Train your team: Bring all your staff up-to-speed on fulfillment options, managing returns, and updated workflows to fulfill omnichannel orders.

- Pilot and scale: Next, test your new omnichannel approach in selected stores or areas, then gather feedback and analyze data. Refine as needed, and then proceed to integrate your new strategy at scale.

- Measure and optimize: Use KPIs to monitor performance and customer satisfaction, and conduct regular reviews of your fulfillment strategy to assess points of friction or inefficiencies.

By following these steps, you should be up and running in no time.

Just remember that scaling your new omnichannel approach is often a case of trial and error. Be patient, use data analytics and feedback to sharpen your approach, and don’t be afraid to get in touch with an outsourcing expert to offer potential solutions to any teething problems.

Best Practices for Omnichannel eCommerce Fulfillment

Looking for some pro tips on how your eCommerce business can optimize your approach to make your omnichannel fulfillment options work harder? We’ve got you covered.

Here are three examples of best practices that you should take note of:

1. Centralize Your Inventory Management

You’ve got to use a unified inventory management system to ensure real-time visibility across all channels.

This will prevent stockouts or overstocking and enable you to offer fulfillment like ship-from-store, buy online in-store pickup (BOPIS), or reserve in-store. It also gives you the flexibility to re-allocate inventory to different sales channels based on channel priority.

To centralize your inventory management, look for a solution like Ware2Go’s FulfillmentVu platform that can seamlessly connect your Order Management System (OMS) or Enterprise Resource Planning (ERP) software to sync inventory across every channel.

2. Optimize Your Fulfillment Locations

Strategically distribute your inventory across multiple locations to reduce delivery times and shipping costs. This leads to faster delivery and reduces the risk of bottlenecks.

Make sure to use a solution that routes orders to the nearest location for fulfillment. To centralize your inventory management, use Order Management System (OMS) or Enterprise Resource Planning (ERP) software to sync inventory across your distribution channels.

3. Invest in an Integrated Tech Solution

Integrate all your systems to create a cohesive omnichannel fulfillment network. That might include sales platforms, 3PL solutions, and warehouse management systems.

This will streamline operations, minimize errors, and allow customers to track their orders in real time.

Automation tools, APIs, and analytics platforms can help you monitor performance and identify opportunities for efficiency.

For example, Ware2Go’s FulfillmentVu platform can seamlessly connect your existing tech stack, sales channels, and eCommerce platforms with Ware2Go’s expansive network. You can then easily add new channels via hundreds of integration possibilities.

Meanwhile, our RESTful API gives you 100% control of setup. It also automatically pushes updates with no interruptions to your end-to-end tech stack.

Start Your Omnichannel Journey with Ware2Go

In this day and age, customers expect freedom of choice. You can meet that demand by providing a range of sales channels and fulfillment options.

By adopting an omnichannel fulfillment strategy, you’ll be able to enhance your customer experience, make your distribution operations more efficient, get better data, and free up time and resources to grow your business. You’ve just got to ensure you’re choosing the right partner to help you achieve those goals.

Offering a range of end-to-end services to support your omnichannel strategy — whether you require ocean freight, Amazon fulfillment, help with seasonal spikes in demand, or anything in between — Ware2Go helps unite sales channels to warehousing and fulfillment solutions using plug-and-play supply chain technology.