COOLERSbyU needed a flexible solution to help them make the most of their seasonal demand cycle. Learn how they leveraged on-demand warehousing to go from a one-man start-up to a profitable ecommerce business.

COOLERSbyU needed a flexible solution to help them make the most of their seasonal demand cycle. Learn how they leveraged on-demand warehousing to go from a one-man start-up to a profitable ecommerce business.

As recent college graduates might know from experience, cooler painting has become a staple of Greek life on college campuses. Although it initially started as a gift-giving custom between sororities and fraternities, hand-painted coolers can be spotted everywhere from tailgates to spring break across the country.

College students purchase and paint tens of thousands of coolers every year, and it’s often a time-consuming process. It can involve hours of sanding, priming, sketching the design, and then painting. That’s where recent college grad Garrett Barretta saw a business opportunity.

In 2016 he founded COOLERSbyU, “ready-to-paint” coolers and paint kits that turned the labor-intensive process of cooler painting into a breeze. The coolers’ prepped surfaces allowed students to get straight to the fun and creative part of the process — designing and painting.

Demand for COOLERSbyU immediately took off. After selling around 50 coolers during November and December of 2016, order volumes skyrocketed to include nearly 1,000 in 2017 and then over 2,000 in 2018. Garrett was thrilled with the response to his product but quickly saw that his internal fulfillment process would soon be overwhelmed at the rate his order volume was growing.

With Ware2Go, I’ve gone from spending 20-30 hours per week packing and shipping orders to having a completely “hands-off” fulfillment process. They manage everything from warehousing through to delivery, and the time-savings alone have been a game-changer.

Garrett Barretta

Founder & Owner

During his first few months in operation, Garrett was only fulfilling 2-3 new orders per week. Given the limited volume, he could easily store the coolers in his garage, package them on his kitchen table, and ship them directly from his home. But as his business grew to 60-100+ per day during peak season, managing the fulfillment process internally became almost impossible. The days of enlisting his friends and family to help fulfill orders during the busy college football season were behind him.

Garrett was looking for three key qualities in an outsourced fulfillment provider:

With Ware2Go he learned that on-demand warehousing could help him maximize on profits from his high-volume seasonal sales. Usually seasonal businesses are forced to choose between locking in costly year-round storage terms with a top-tier 3PL or keeping fulfillment in-house and straining their internal resources. However, with on-demand warehousing, merchants pay only for the warehouse space and labor they need when they need it. This means they can save on fulfillment costs in their slow season to maximize profits from their peak season.

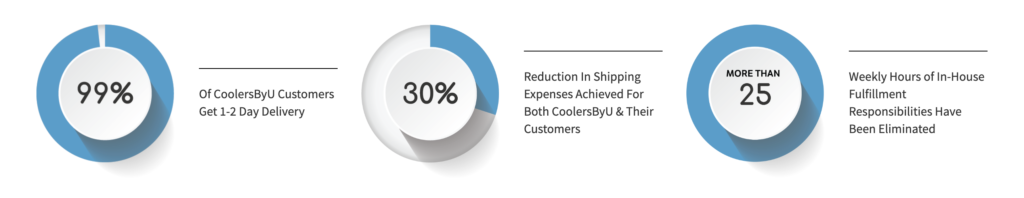

Additionally, with Ware2Go’s distributed warehouse network, COOLERSbyU was able to store inventory closer to their end customers to reach 99% of shoppers with 1- to 2-day ground shipping. This enabled them to meet their customers’ expectations for fast shipping without relying on costly solutions like next-day air.

All-told, the supply chain improvements COOLERSbyU realized by partnering with Ware2Go gave Garrett the flexibility to grow his seasonal side-hustle into a profitable long-term business. With fulfillment off of his plate, Garrett has had the bandwidth focus on growing his business through developing additional product offerings and increasing his reach through social media marketing.