Having an automated warehouse network is becoming essential for multichannel selling. See how growing businesses are using automated warehousing to scale operations and optimize their bottom lines.

Fast-growing companies know that technology is key to remaining competitive in today’s marketplace, especially in an omnichannel selling environment. In a recent survey on the future of fulfillment, decision makers pointed to three key needs in logistics management:

- 38% A desire for an end- to-end solution

- 31% Ability to scale and automate

- 36% Comprehensive logistics technology

The good news? There are solutions available, many of which are turnkey. However, the 3PL model is changing and not every solution truly creates an automated warehouse network that meets today’s challenges. Let’s start by defining what the right automated warehouse solution should look like.

What is an automated warehouse network?

An automated warehouse network is a combination of a Warehouse Management System (WMS) with a national warehouse network. When technology intersects with physical warehousing, distribution, and delivery it creates a powerful, holistic solution for emerging brands to scale with ease.

Let’s take a closer look at what every automated warehouse network should have.

Implements cloud-based software that automatically optimizes the supply chain

Disjointed technology and manual tracking can be time-consuming and inefficient. Likewise, managing logistics can pull employees away from their specializations. However, with unified technology, fast-growing companies can have peace of mind that every step of logistics management- from ocean freight to last mile delivery- is being accounted for and optimized.

STAT: 45% of recently surveyed decision makers would like to divert their team’s time away from logistics management and back towards their core competencies.

Captures customer insights and inventory trends for smart warehousing

Optimizing operations throughout the supply chain should happen in real-time and use predictive technology to spot consumer trends. With an automated warehouse network, inventory can be distributed based on product sales, geography, and sales cycles (e.g. peak season) to maximize shelf space. The ideal WMS should instantly analyze sales and logistics data to automatically distribute inventory to the right warehouse at the right time to avoid stockouts.

Critical to on-time delivery, a WMS should also optimize the pick pack and ship process within a warehouse. When both large scale operations and day-to-day work are streamlined, merchants unlock the full benefits of a digital supply chain.

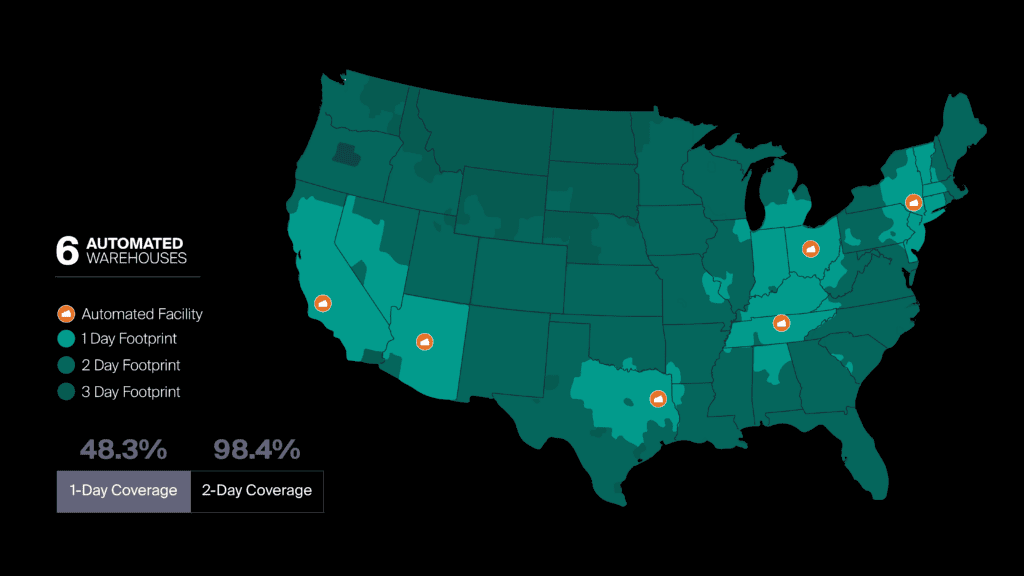

Creates a national warehouse network for 1- to 2- day shipping

An automated warehouse network is not complete without physical warehouse space. As many emerging brands are choosing to outsource warehousing, there is opportunity to secure much-needed land cover to meet customer expectations of 1- to 2-day shipping. With a network of on-demand warehouses, merchants can now meet those expectations- whether they sell on Amazon or not. Many merchants are finding affordable options- including co-warehousing with major brands.

What are the benefits of an automated warehouse network?

Emerging brands trust automated warehouse networks for four main reasons:

1. Lower expenses: By avoiding the costs of capital, resources, and time required to operate and maintain their own storage facilities, merchants can instantly start stocking product lines and shipping to customers.

2. Scalability: Automated warehousing allows for inventory capacity to grow in proportion to sales velocity by relying on robotics and automation rather than labor. And in an uncertain labor market, automation is the key to increasing certainty- including resilience to market shocks.

3. Versatility: Public warehouses often provide month-to-month leases and provide a wide variety of locations across the country, which allows fast-growing businesses to move their goods to fulfill customer demand.

4. Strategic: With more businesses turning to ecommerce, merchants can rely on an automatic warehouse system to place inventory close to their consumers, ensuring speedy delivery in 1-2 days, all while maintaining optimal profit margins.

Partnering with big retail brands for co-warehousing

A vast majority of decision makers at mid-sized businesses recently reported being open to co-warehousing with major retailers. In these partnerships, businesses can tap into enterprise-level supply chain capabilities and supply chain networks without making the capital investment in expensive warehouse robotics.

Partnering with major retailers rather than building their own facilities is an opportunity for fast-growing companies to de-risk their operations. By avoiding initial- and ongoing- investments in infrastructure, hardware, and warehouse upkeep, merchants can instantly remove traditional costs from their balance sheet, shifting to a variable cost model as opposed to a fixed cost model.

With the right 3PL, merchants have a neutral third party that ensures:

- Products will never be de-prioritized during peak season in favor of the major retailer

- Flexibility and ability to pivot when supply chain issues arise

- Transparent and independent inventory data and customer data

- Retailer(s) will never request customer data from co-warehousing merchants

- A direct and easy integration and open API

Ware2Go is proud to partner with the GAP in a new era of warehousing. GAP warehouses offer Ware2Go customers world-class robotics in automated facilities. Meanwhile, GAP warehouses offer advanced material handling systems- ideal for high velocity fulfillment of product categories like apparel and footwear.

Through co-warehousing, Ware2Go has expanded its automated warehouse network to include six new warehouse locations with network-wide inventory visibility and delivery insights.

With a growing interest in automated warehouse networks, the D2C marketplace is being redefined- for merchants and for their customers. To learn more about co-warehousing or Ware2Go’s automated warehouse network, fill out the form below.